I have been keenly following Mike's progress on this project and I'm very pleased it has progressed this far, so quickly. So before I start, I'd like to thank Mike for his efforts, and I hope that this guide presents the product in the best possible way. Now I'm like most electronic enthusiasts, I was brought up on Dick Smith and Tandy "do it yourself" electronic kits, so I was really looking forward to building this MPU. I have plenty of experience repairing and rebuilding this MPU board and I've succeeded in bringing back some boards that others would have thrown out. I see those boards as a challenge, but they are TIME CONSUMING to repair. The Altek board has long been an adequate replacement board, but it is always a costly replacement. I have an Altec board that I use - but only to test in my Bally and Stern machines while restoring. I seldom leave them in a game for long periods. I like the idea of the ORIGINAL MPU. That's why I'm VERY keen to see this format almost REPLACE the Altek for Bally and Stern games. Don't get me wrong - there IS a place for Alteks, but it is not cost effective to buy one for the sole purpose of replacing a corroded and fatigued original board. That's where the HOMEPIN board fits in nicely. I have over 20 Bally and Stern Games, and I would use the Altek during the restoration, and then either use an adequate original board, or a Homepin board. I understand circumstances will be different for everyone, but that's where I see this product heading. I fully restored KISS should either have a pristine original MPU, or a Homepin MPU board BEFORE an Altek. Thats because I'm a purist and I like the originality of this board in front of an Altek.

Enough of the dribble

A pizza delivery man dropped off a package early this week, even though I had not ordered one !

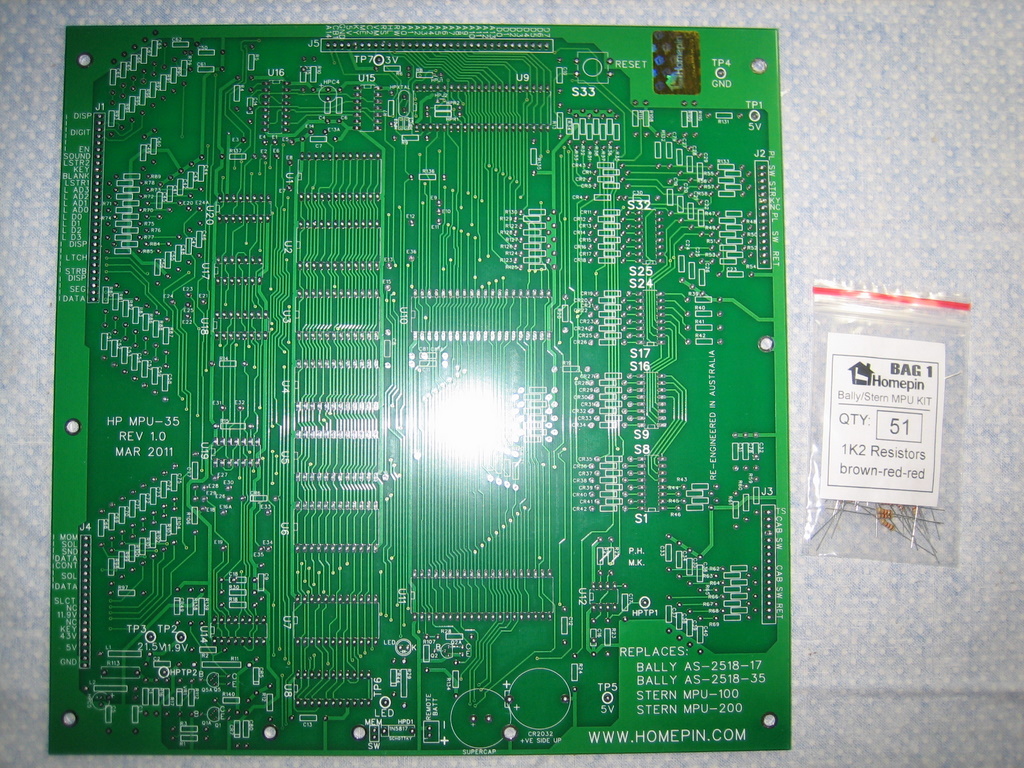

When I opened the package, everything was packed very well and I was surprised that everything fit so easily. Here's the contents of the kit ;

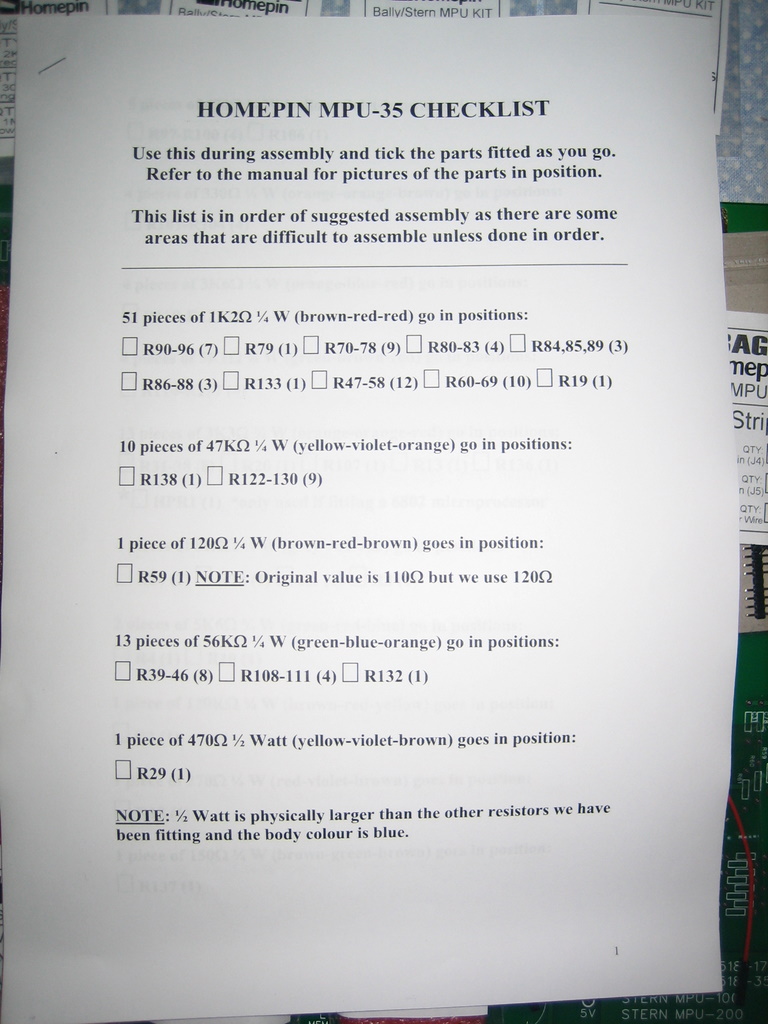

An easy to follow checksheet comes with the kit as well as the instructions on two different SD cards. I didn't look at these throughout the assembly. I'm ther kind of person that does not read instructions. I like to "dive in" and get started. I think the printed instructions will suffice for now ! Notice how all the bags are individually labelled and correspond to each step of the assembly. This is a really nice feature of the assembly process, as you really just need "common sense" to follow it rather than a master's degree in kirchoff's law !

So you basically pick the bag that corresponds with the documentation. Simple enough. As I went through the process, I recorded the time I spent for that given step. This will give me an indication to the amount of time to complete a board.

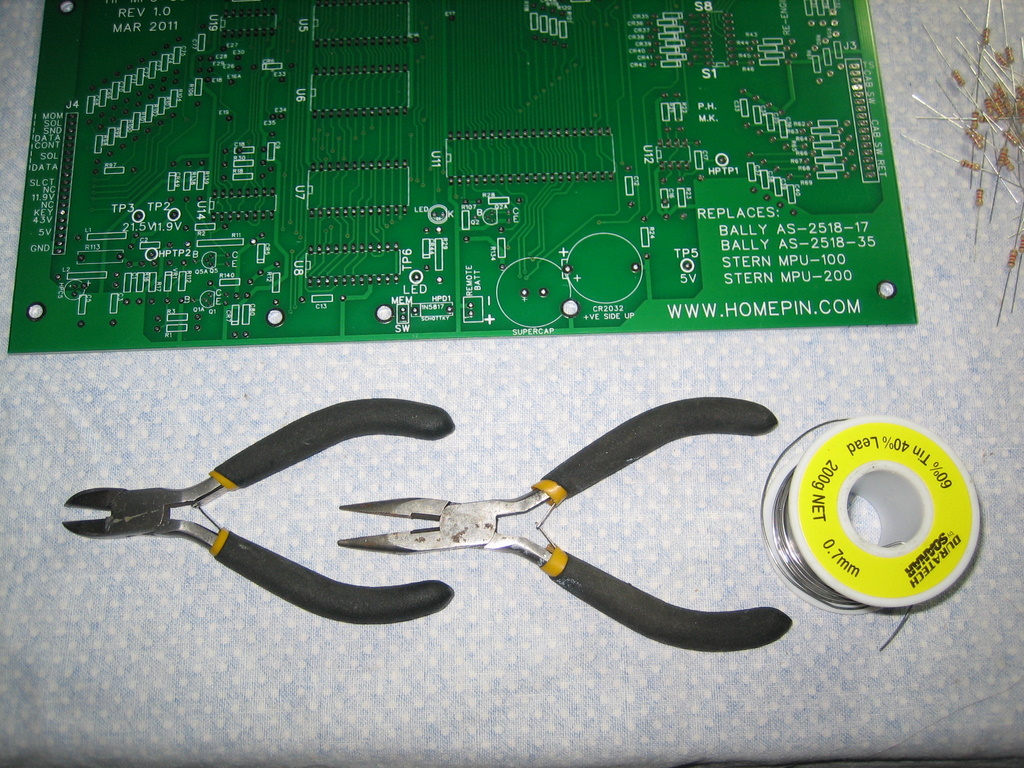

TOOLS - Important to have the right tools for this assembly. I have an "AOYUE 701A" which is a Chinese copy of the Hakko 701. Different is around $800. It is a soldering and desoldering station. I recently bought a new set of tips specifically for this assembly. The Station cost me $300 delivered (around 18 months ago). You only need a soldering station for this job - these can be bought locally at any Dick Smith or Jaycar. Buy a temperature controlled iron with a fine tip.

Sidecutters and needle nose pliers. These are "trojan" tools I bought at Jaycar years ago for $8 each. Solder was also bought at Jaycar.

Page 1 - Step 1

The PCB itself is really well made. There are some observations I will make towards the end of the build that may or may not be part of the next revision of the board - suggestions more than anything else.

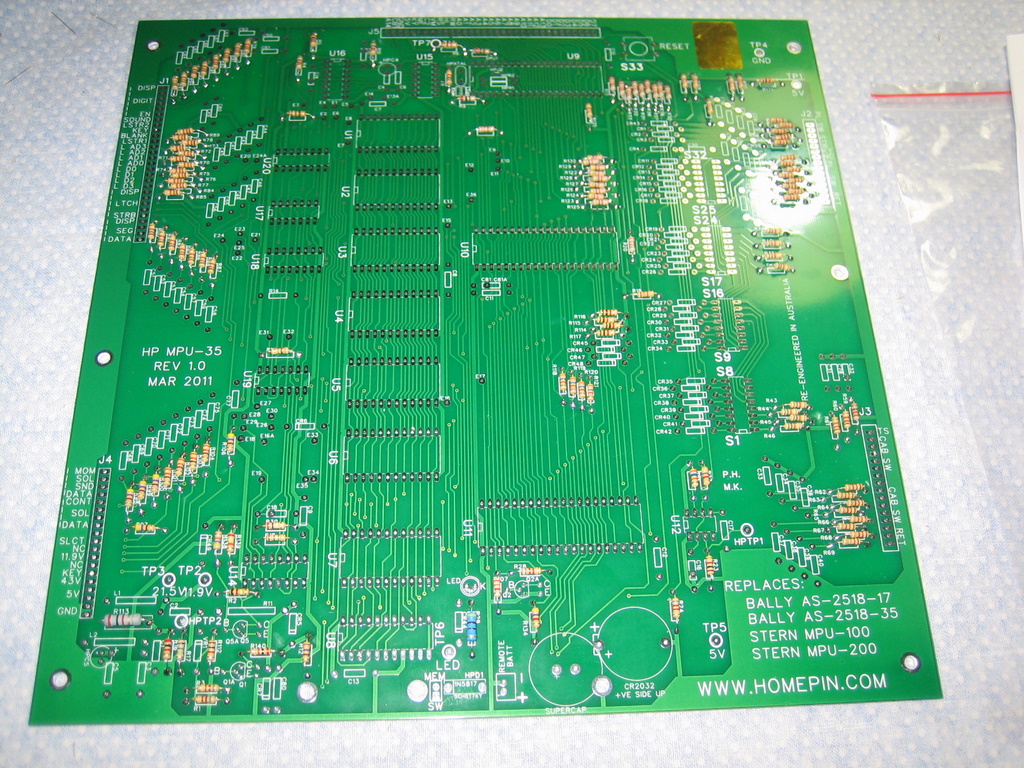

"Bag 1" is 51 1.2K Resistors - even the colors are denoted on the notes in the bag. Simple enough. Took me 20 minutes. I solder both sides of the board with a fine point on my soldering iron

20 minutes later ..

There's around 3 pages of resistors to install. So a quick fast forward ahead to the point when 90% of the resistors are installed on the board. This was simply a case of following the printed guide and checking each stage with the relevant bag of parts. Too easy !

We do the same for the capacitors, diodes, sockets, test points, switches, transistors, inductors and battery housing. I'm at this point as of tonigh. I have not compiled the exact time, but I'm almost there and it looks to ne coming along VERY nicely !

So far - I've really enjoyed the process

Observations in the documentation that will need to be updated

Bag 9 has a 10K resistor leftover. This would be R14. I can't find it in the doco.

Page 5 - Microprocessor selection chart for 6800 - Use the jumper HPJ2 - The holes are present, but not much of a solder pad. This may be an issue with connectivity. It looks to be the same for all jumpers. I would like to suggest larger solder pads.

Page 6, the Capacitors are listed, but not where they belong on the board

C14 - 470pF (471)

C15 - 470pF (471)

C16 - 0.1uF Greencap (104)

C18 - 0.047 (473)

C32 - 0.003 (332)

Page 6 - installation of Q1, Q2 and Q5 - The original solder holes are fine - that's how I installed them. The new holes are too small for the transistor legs and there is hardly any solder pad to mount them.

Page 6 - 82 Ohm 2W resistor. The rightmost eyelet is VERY close to CR5's solder pad. I didn't use the eyelets.

I'm REALLY pleased with the build so far, and the above notes on the doco are only a MINOR thing which I'm sure are easy fixes. I must say I've very impressed, and I can't wait to finish the board and install it into my Viking. I'll contime the guide in the next coming days