Nice to see a FH restoration, one of the true classics.

Was the 'professional' decal job one of the Melbourne dealers?

Apparently so..

The most annoying part is the lack of preparation. The decals were knock offs, but would have passed as originals. I've had a professional with years of printing experience determine it was not screenprinted, and a fellow restorer who has done several Funhouse re decal jobs agree. The short cuts are astounding. This was their "High End Restoration" standard. Even the top of the headbox was not even cleaned - I cleaned that several times - it was filthy !

Having said that, the playfield swapover of this machine (with the redecalled cab) was very good !

Moving on..

The playfield components both above and below the playfield are checked, cleaned and tumbled. I hand polish screws etc on the buffer. After this step, I check all the parts that have been broken or compromised. In this case, there were many. Unless a thorough inspection is done, it can be hard to find broken parts that are hidden from normal view, and effect the gameplay. Here's an example ;

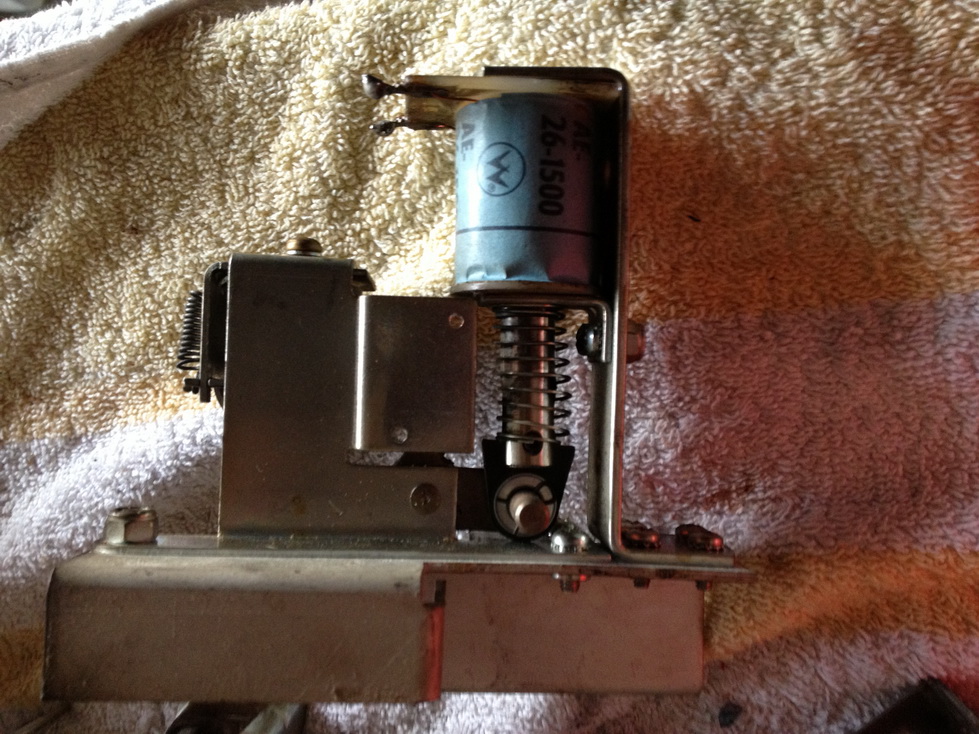

Trapdoor assembly is removed and looks fine - just filthy !

But look at the lubrication that has effectively seized the assembly. I also verify each plunger to see if they are the correct ones for the assembly. This game had Bally SS plunger and links on the slingshot assemblies.

Here's one container of filthy parts. They are degreased, washed in water and then metho. From there, I put them in the plunger for a day.

Then I sort them out prior to assembly ;

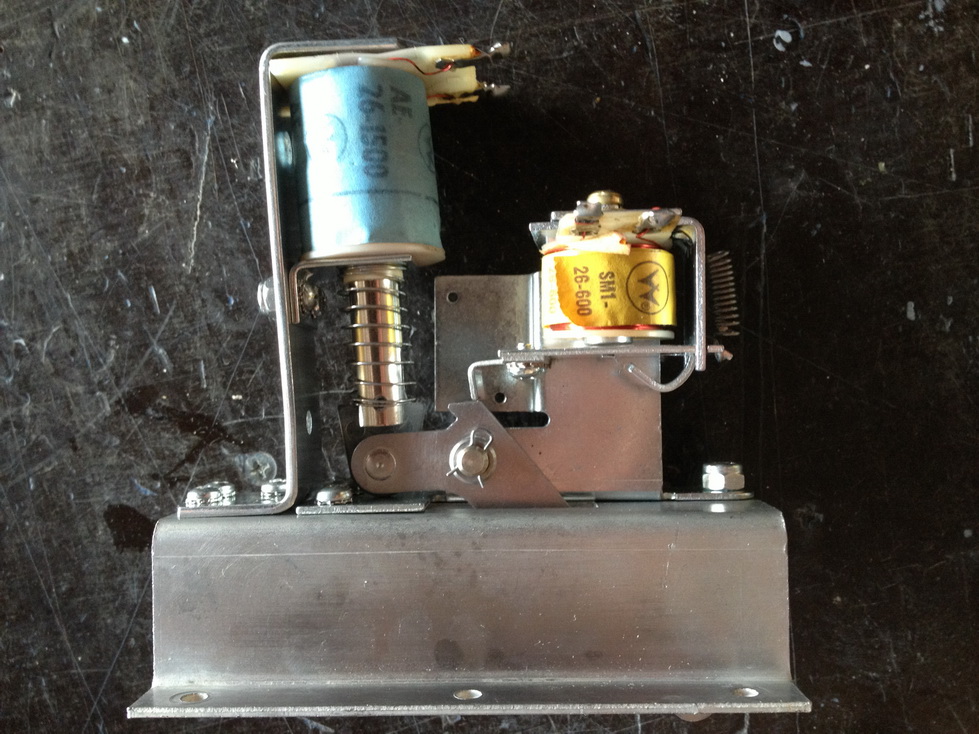

Major assemblies are rebuilt. New coil sleeves, correct coils and also springs if they are needed.

Here's the rebuilt trapdoor assembly. Works 100%

Next will be more playfield assembly and the Next Gen cab decals which have arrived ! I've also kept Greg busy with parts from RTBB and the PinballInc Ramps have arrived. So it is all coming together