My cleaning methods depend on what I'm cleaning, but a general rule of thumb follows this process ;

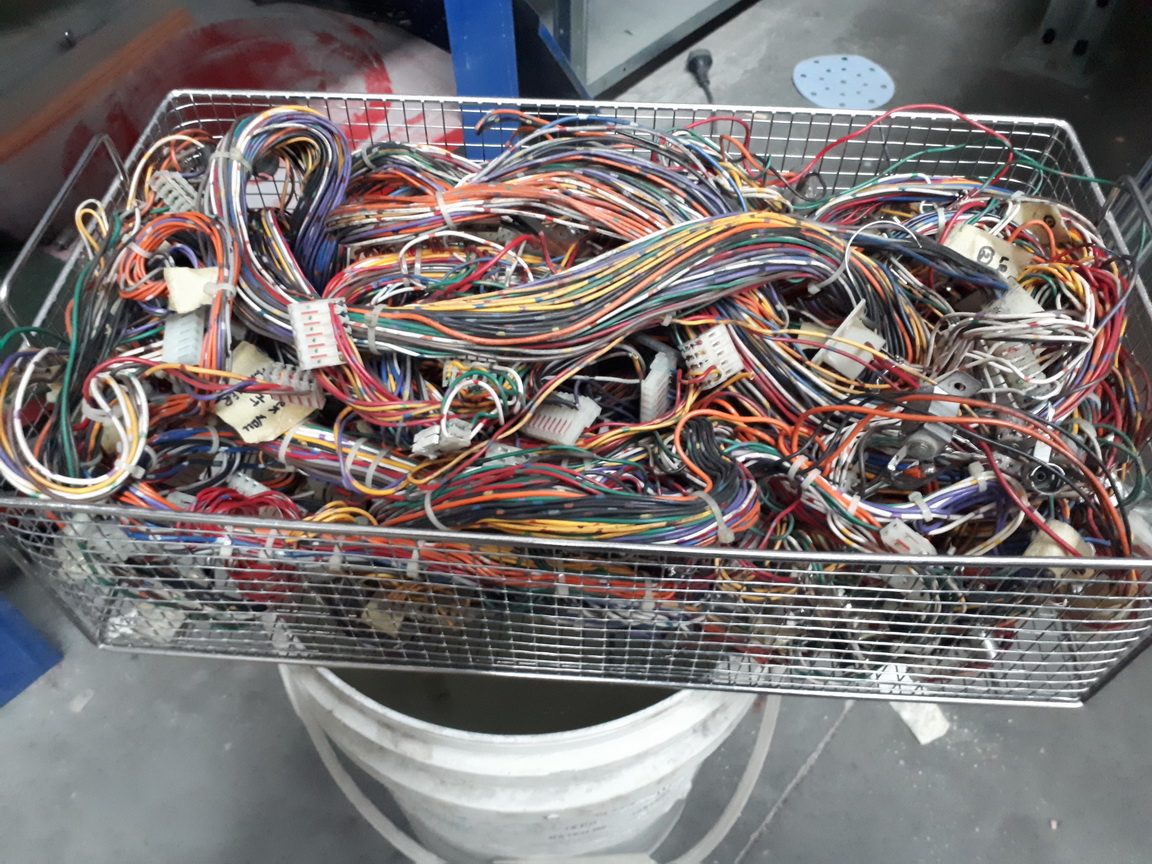

1 - Separate parts into bins - metal, plastic, PCBs, wire looms and parts that cannot be put in the cleaner.

2 - Run them through the Ultrasonic Cleaner

3 - Run Metal parts through the Tumbler (course)

4 - Run Metal parts through the Tumbler (fine)

5 - Clean Plastic parts with Novus etc

6 - Place cleaned parts in parts bins for that machine

7 - Identify parts that need replacement or repair

Here is the playfield wiring loom placed in the Ultrasonic Cleaner's tray.

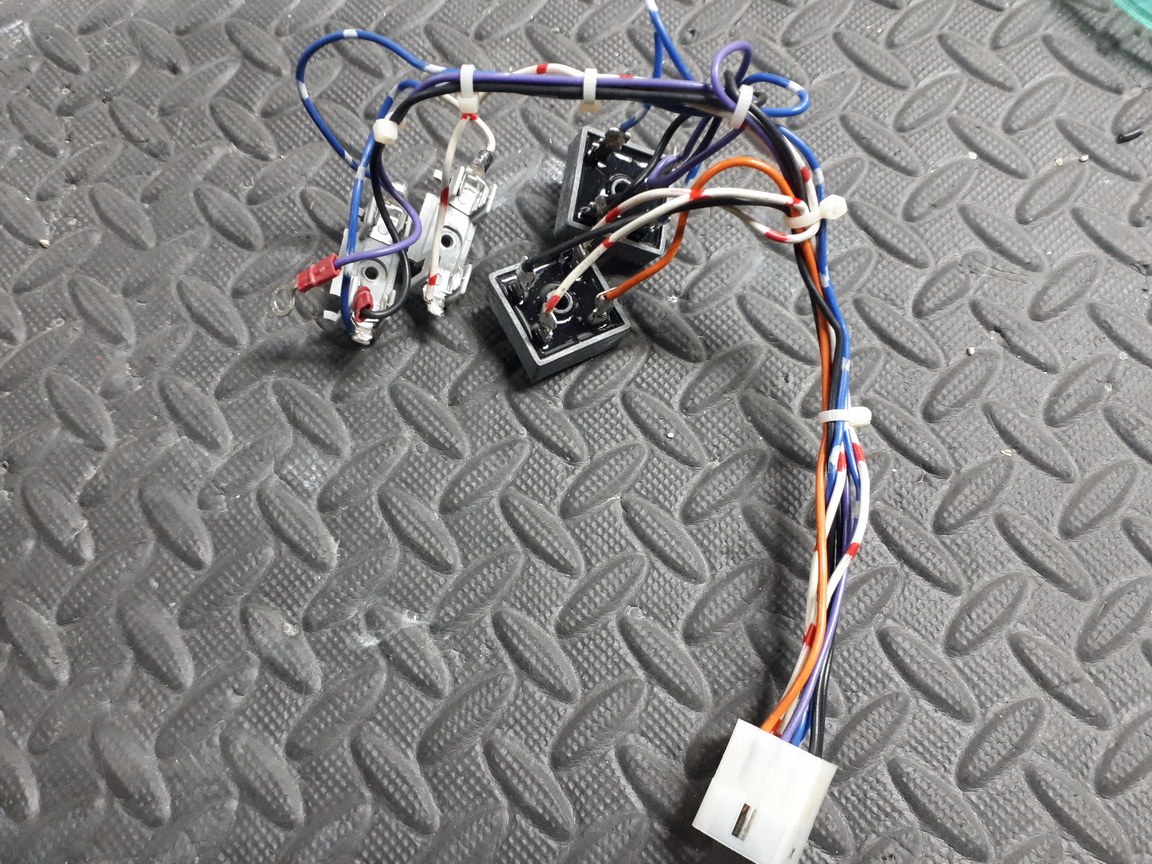

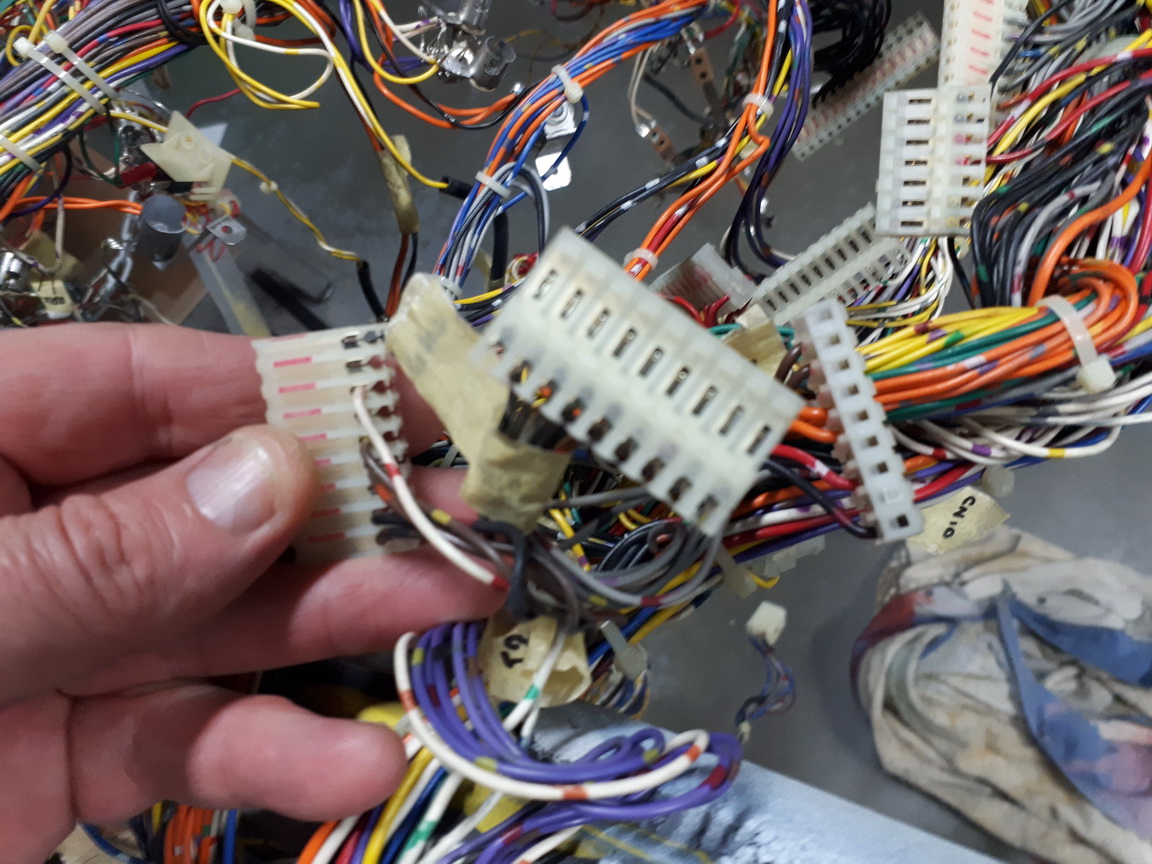

Cleaned section often 30 mins in the Ultrasonic ;

Cleaned Connectors ;

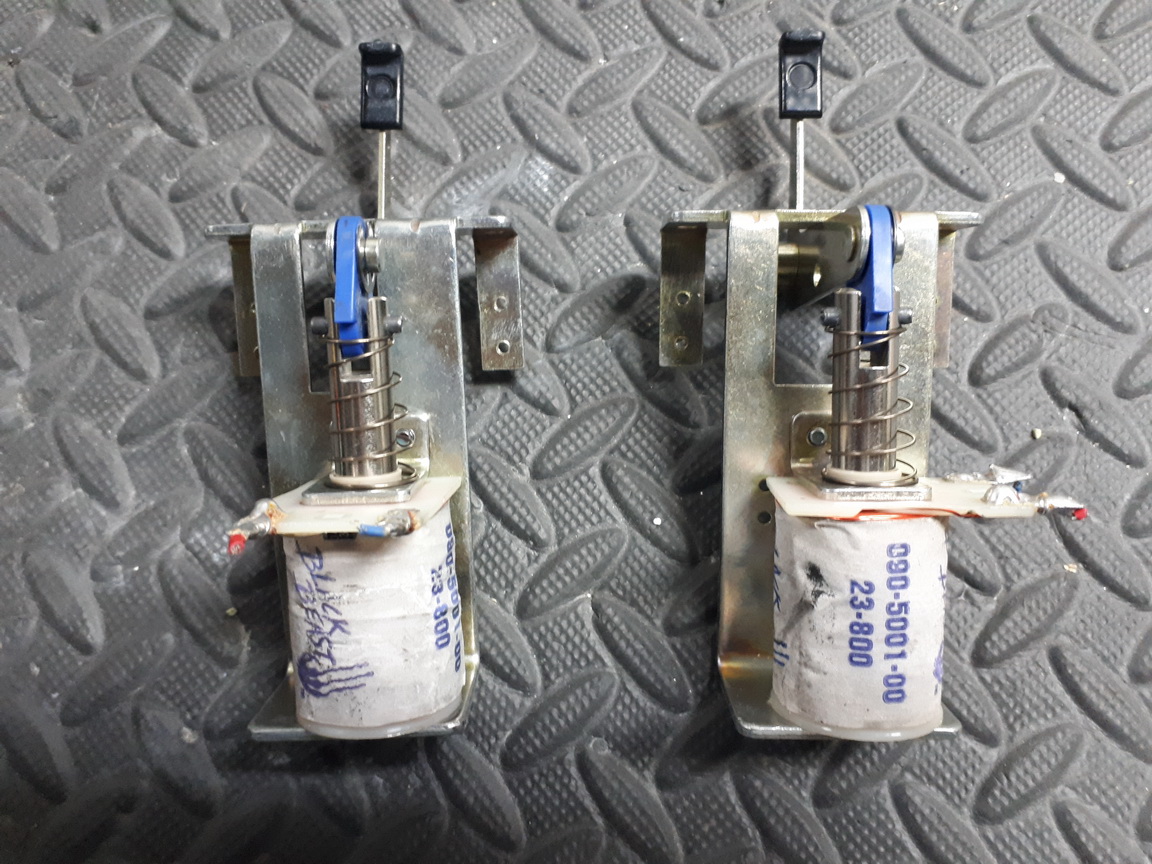

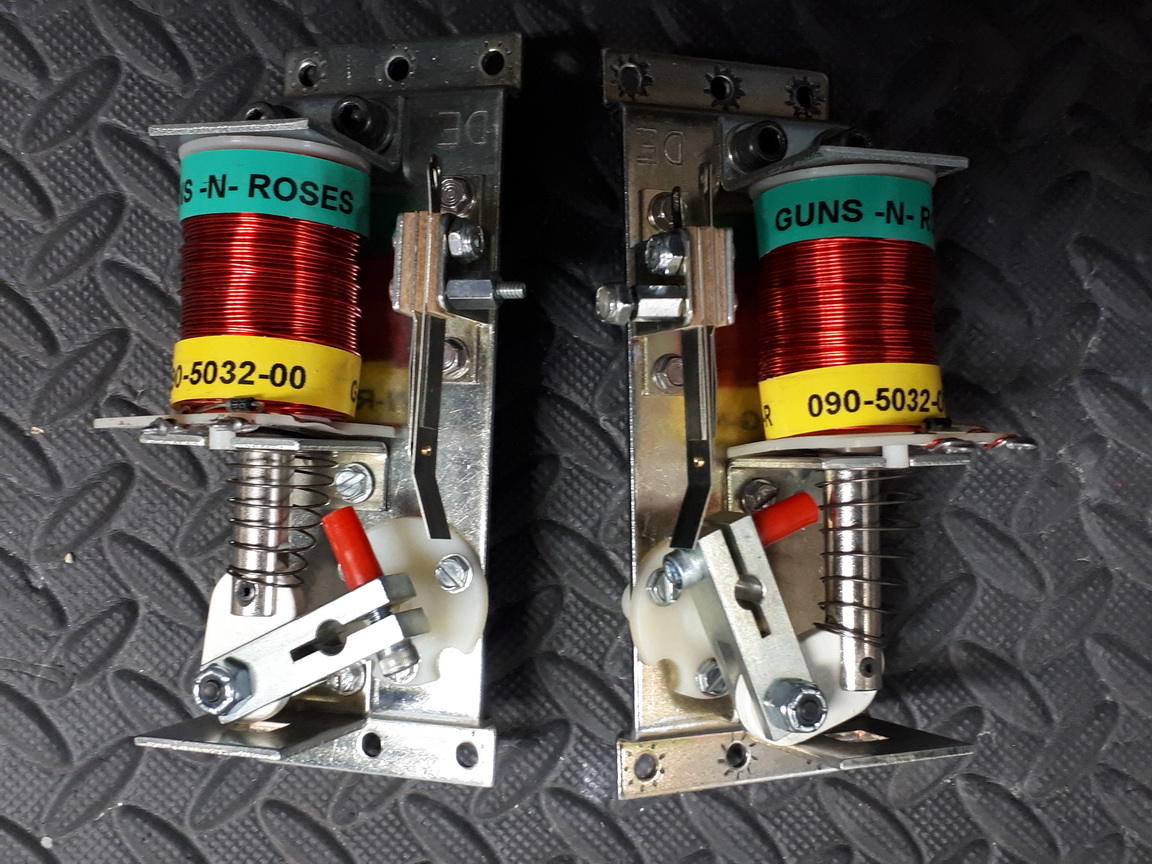

Filthy Mechanisms are also stripped and cleaned. Coil sleeves replaced. Springs replaced. Incorrect / broken parts replaced ;

More updates soon