Time to collate all the parts that I intend on plating. These are stripped, cleaned in the ultrasonic and put aside while I prep the zinc plating bath. I had to replace the old plating bath contents as it was becoming inconsistent.

Those Flipper bases are filthy !

Various parts that need repair

I learnt a lesson with plating Stern parts - They are very lightly plated from factory, and the metal is poor quality. It is a softer metal, and the thinner the piece, the poorer the outcome. Thick pieces plated better. I most likely will not plate Stern door parts again as several parts had to be replated several times, and to strip the fresh plating was a nightmare. Thicker parts turned out as expected.

Here are some parts in the pickle (Hydrochloric Acid and water mix). This strips the old plating. Usually, a part will take 15-20 minutes to strip. Stern parts are so lightly plated, it took less than a minute.

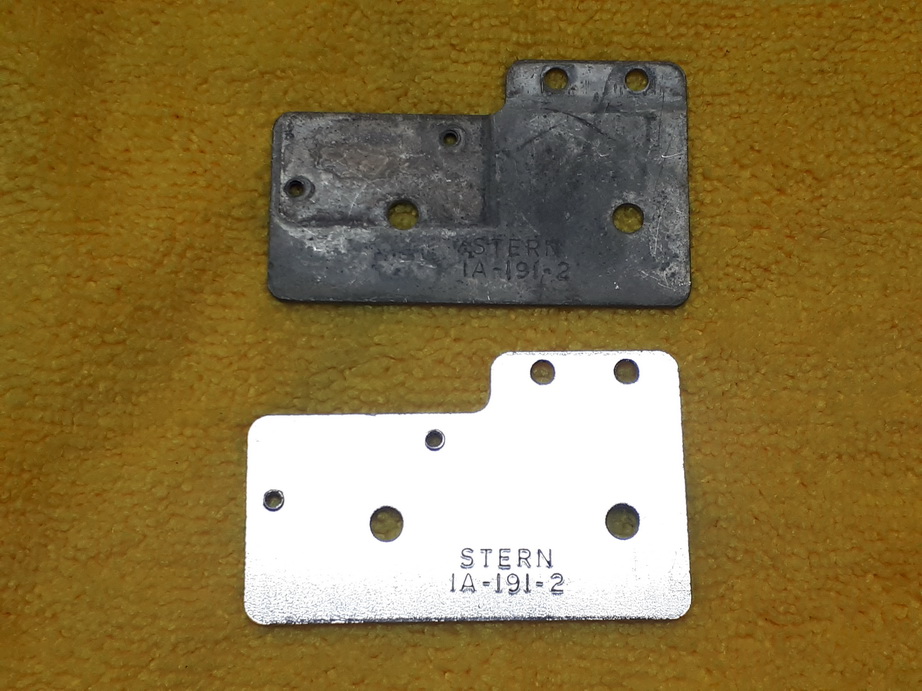

Here is an example of thicker parts - The flipper bases turned out well. Here is a comparison ;

Slightly thinner pop bumper brackets - Not as good, but better than it was ;

Coin door microswitch plate - Turned out really good and was clearly a different metal - that's why it was a good result.

Coin door bracket - not too bad. Still not as good as a Bally or Gottlieb equivalent, which I've plated several times ;