This machine has progressed a fair way since the last update, so it might be a little "erratic", but I won't post everything at once.

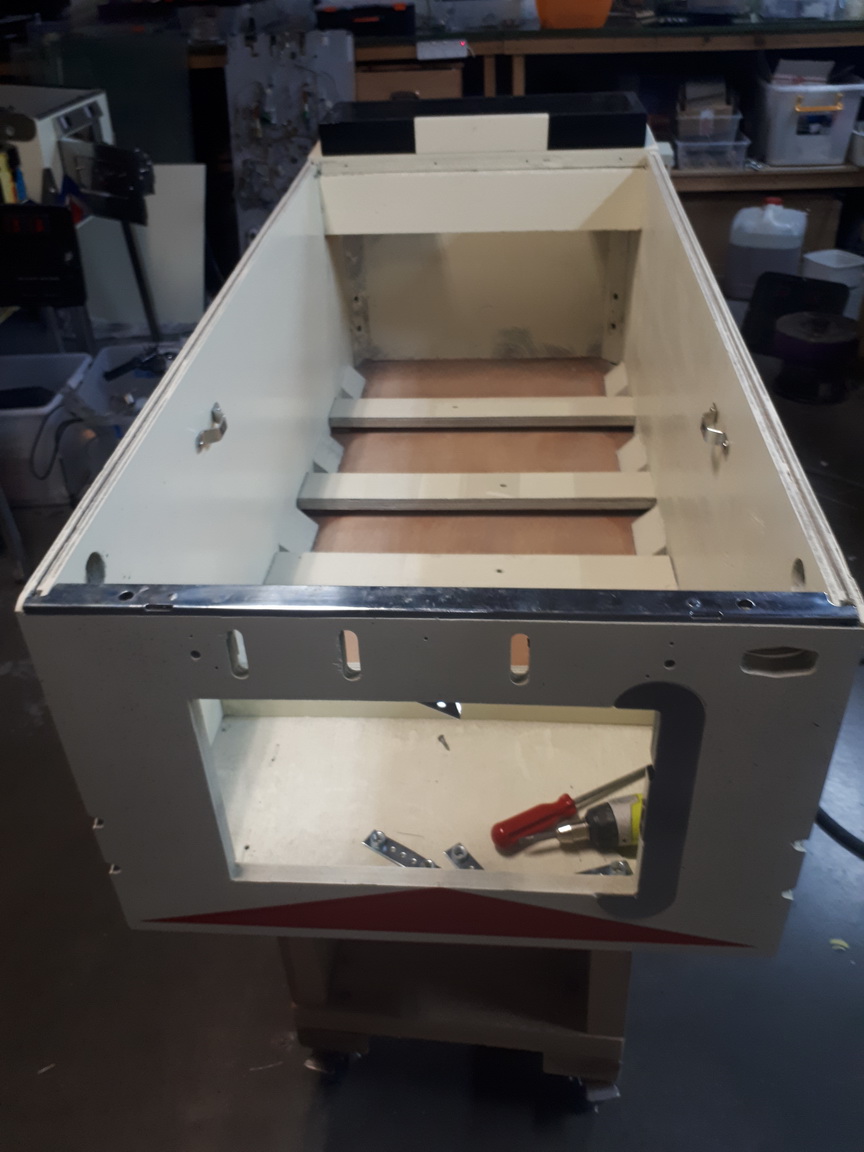

The cabinet hardware was next in line and we want the old parts looking as new as possible, so a lot of the work was done re-plating, which as I've mentioned before, I do "in-house". I have the process well advanced than when I started, but it can still be a challenge with some older parts that are too big for the bath. The door is something I like to start with because the skin is available from PBR, so everything on the inside must be perfect !

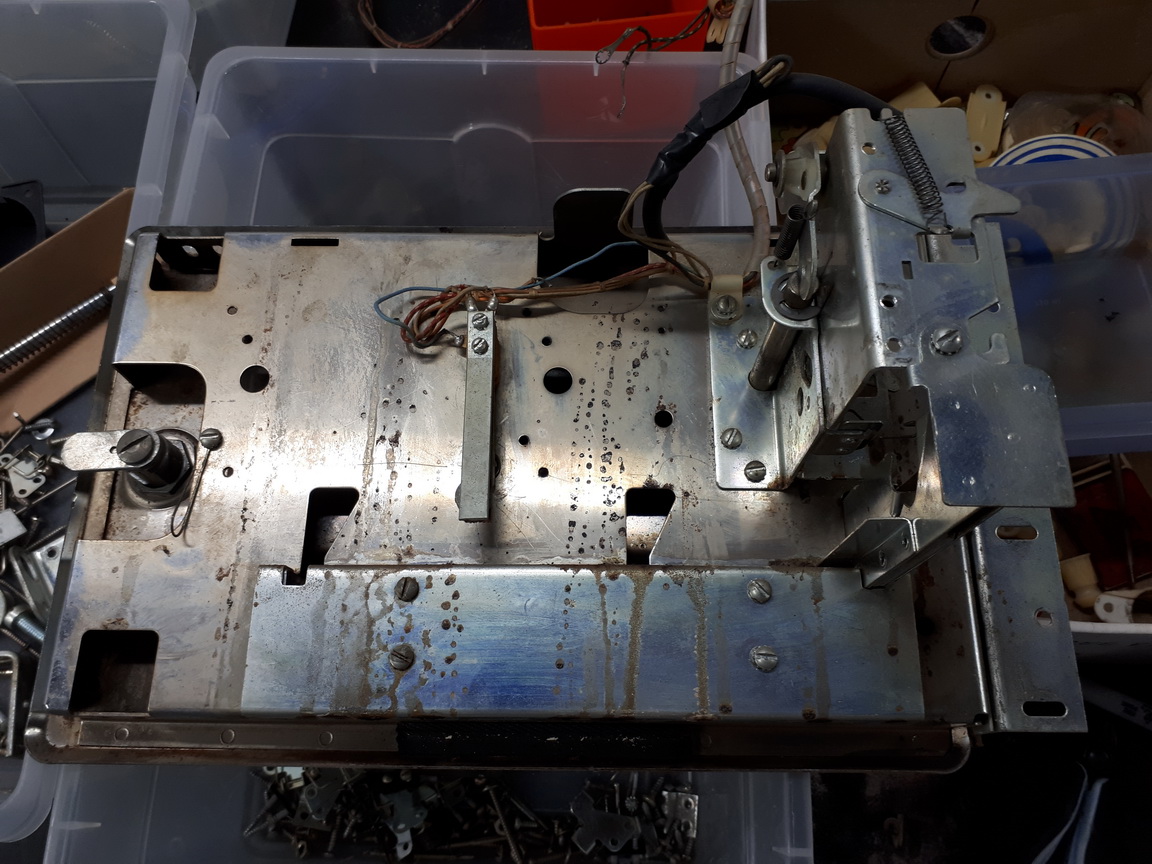

Here is the inside of the door ;

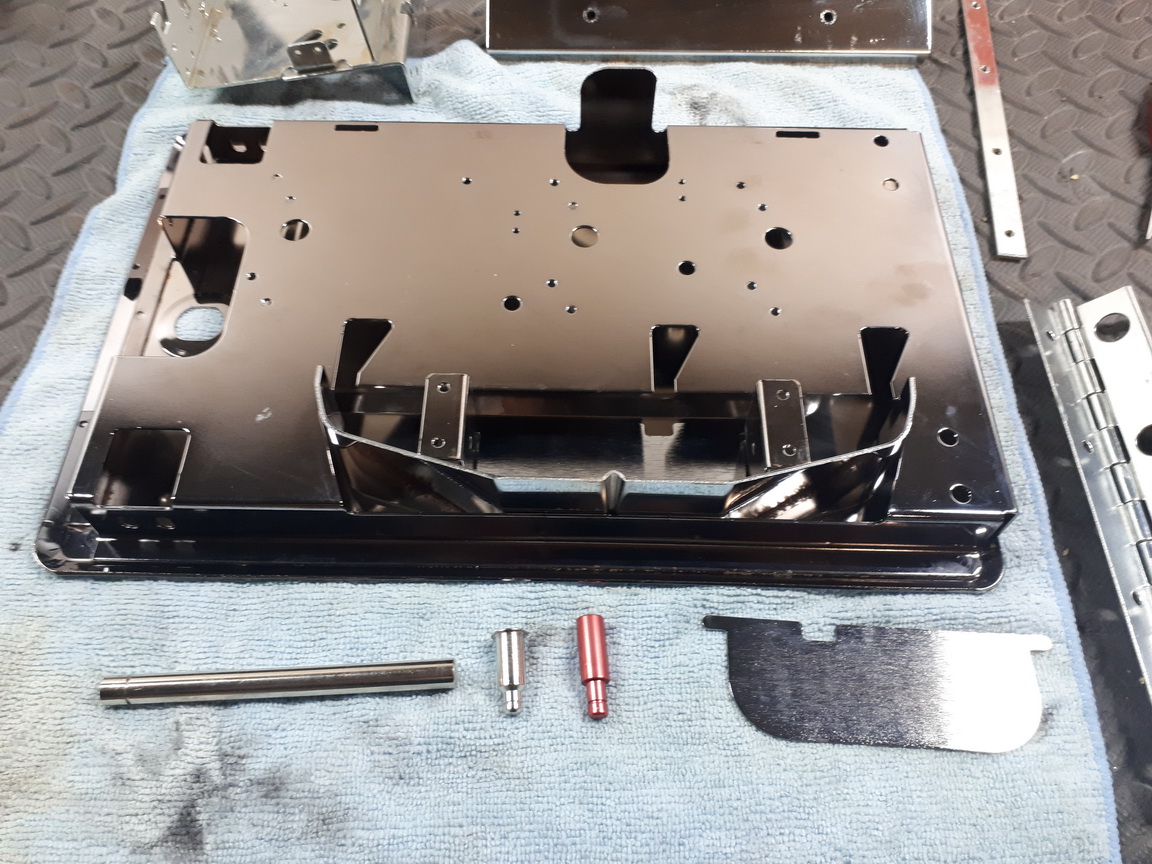

The NEW parts from PBR are all set out and ready to install once the inside parts have been plated ;

The Chimes need a fair bit of work as well !

The Credit Assembly has some rust. These thicker parts are easier to plate and always look great when plated ;

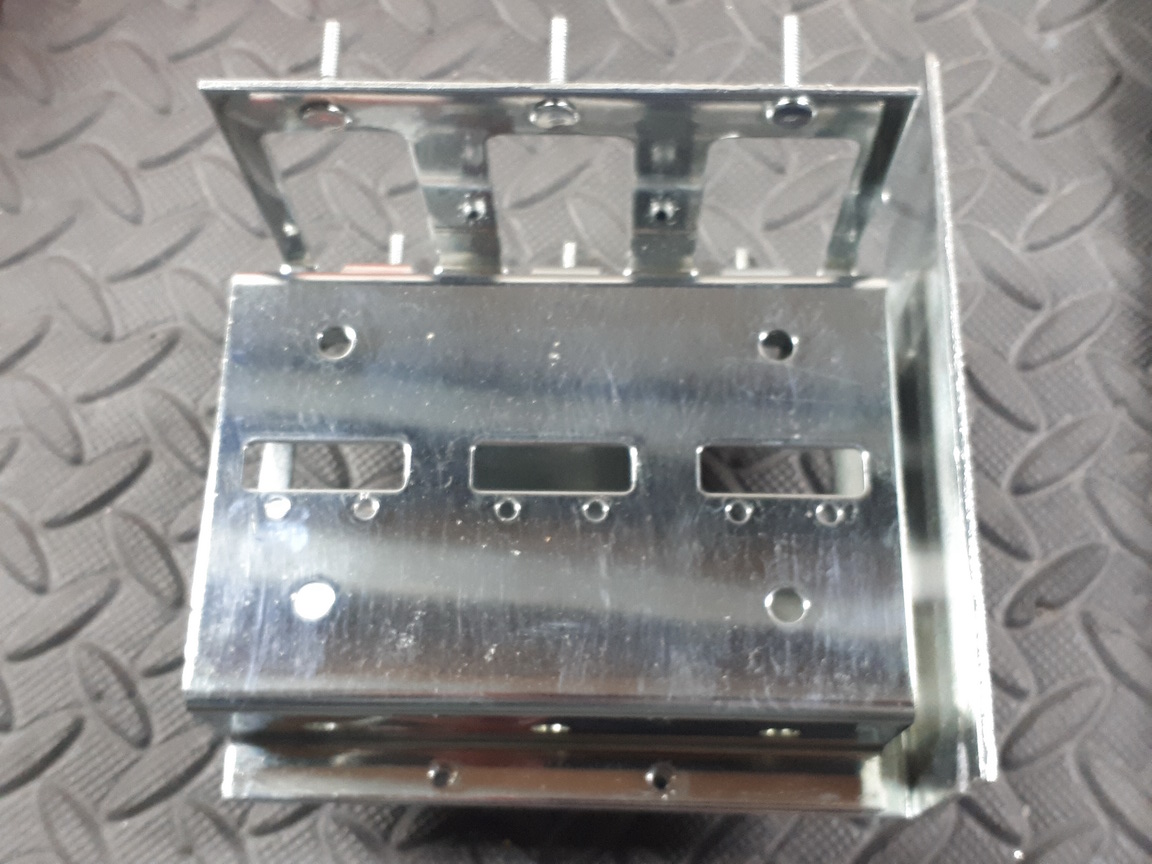

It is always a challenge doing larger parts, and these coin entry plate brackets are usually rusted, bent or broken. Once I have repaired and straightened then, I plate them at the same time as I had to use a different sized bath ;

The Lock Down Bar acceptor is an absolute NIGHTMARE to plate. Platers will not touch these as they have moving parts. I managed to plate them myself, which I was VERY pleased with, but they are VERY hard to get right.

Chime Box was really easy, although fiddly !

Even the plate for the on/off switch is plated !

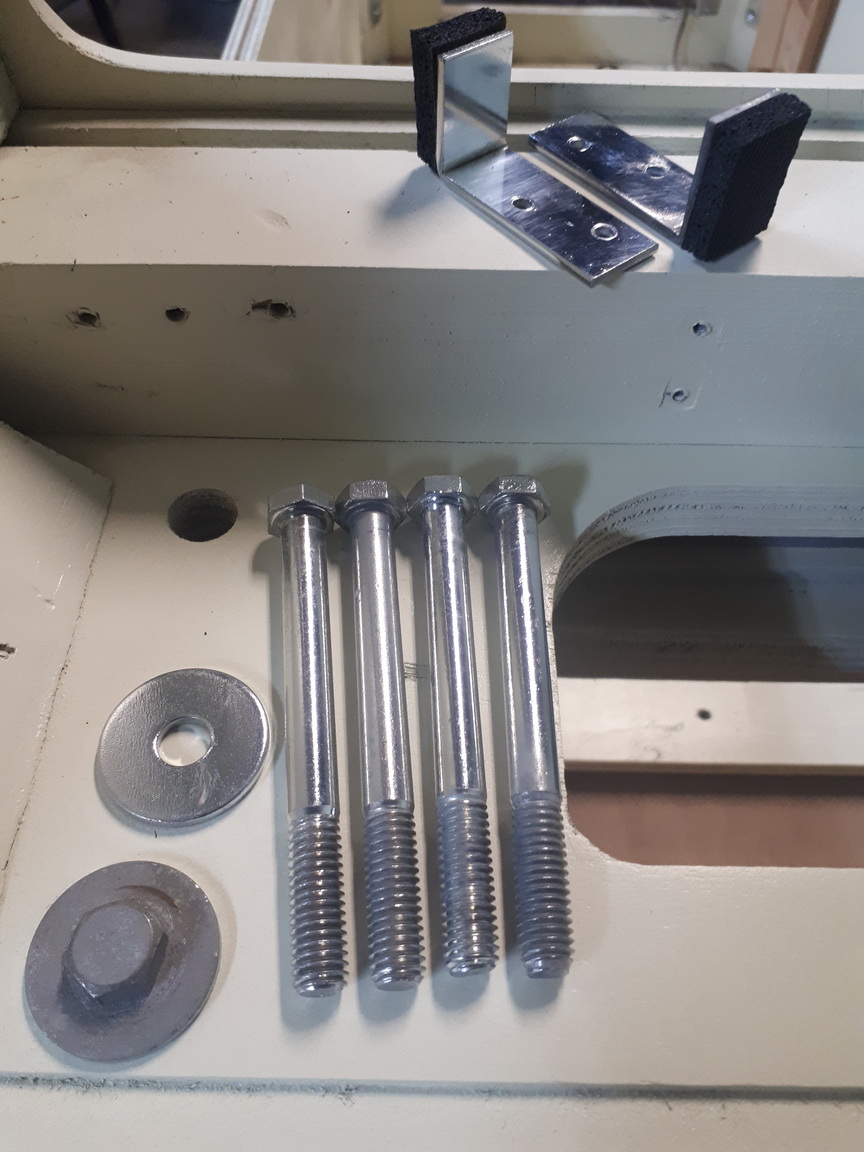

Old VS New Headbolts. Yes, even the washers are replated... The brackets for the headbox as well.

.. and a sneak peak of the door..

HEAPS more to come...