A game I completed last year, but didn't document. It is a game I reconditioned for a friend for his son's Birthday.

ObjectiveThe game will be done within a budget. I rarely do this, but it is a game that I like to present at a high standard, but at a realistic price. Just because it is a "Striker Extreme" container filler, does not mean that when the game is done correctly, it can be a great player.

Condition ReportPlayfield - 8/10 - Mylar. No wear. No issues to deal with unless a problem occurred with the factory mylar removal.

Cabinet - 8/10 - scuff marks around the flipper buttons.

Translite - 10/10 - no problems

Electronics - 9/10 - Battery socket needs to be replaced. No corrosion

"Before" PicturesStraight out of the container (but hand picked - not a usual filler).

Dull playfield with the mylar installed.

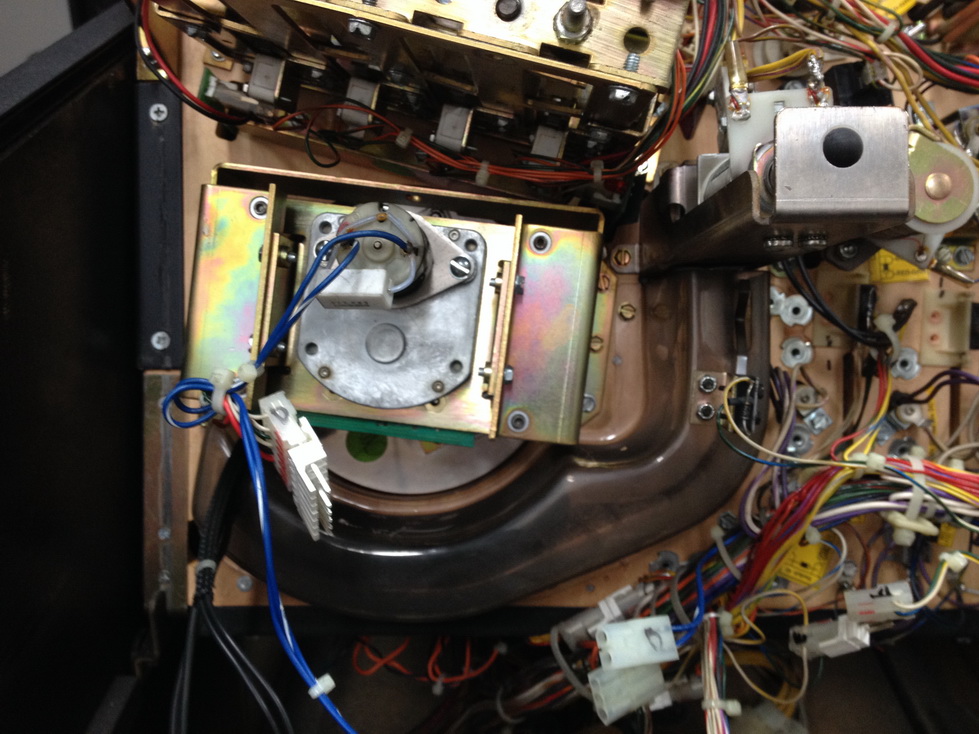

I see this on almost EVERY "shopped" game. The subway ramps are rarely cleaned. No point in working on the playfield without cleaning this area.

As per the STANDARD - The cabinet is stripped, cleaned and then reassembled with clean and polished parts.

MYLAR removal !

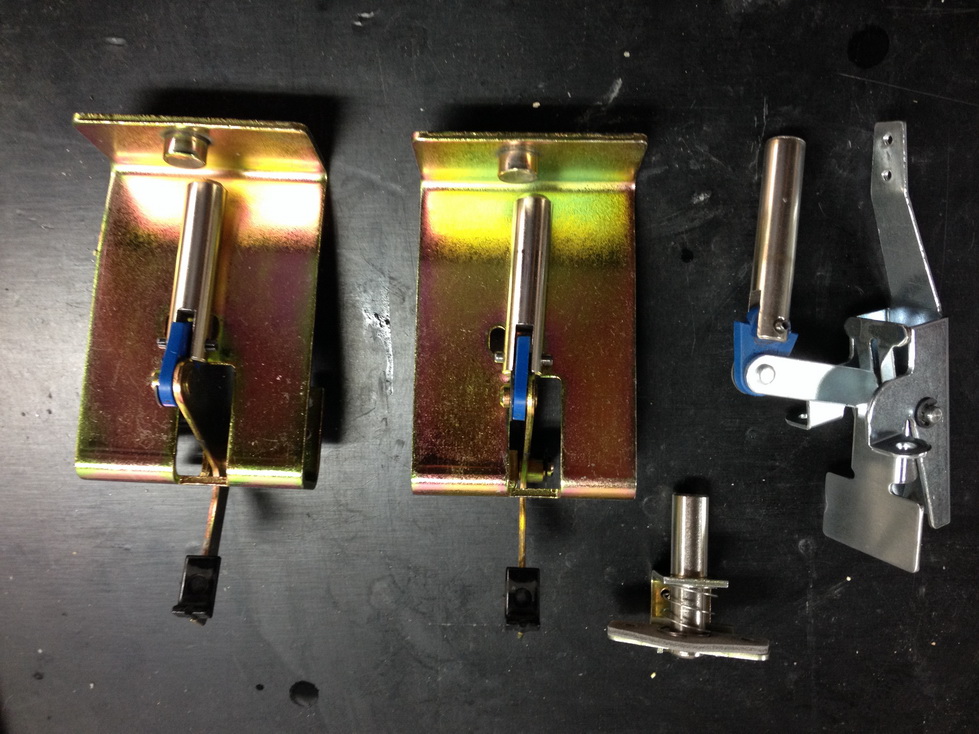

As per the standard - EVERYTHING rebuilt - broken parts replaced as with coil sleeves etc..

Playfield is completely stripped.. or is it ? The metal guides are left in situ because removing them almost always results in the area with the hole being damaged. During the polishing process, these are cleaned and polished and look great.

Mylar removal, clean playfield and then a lot of polishing..

Re assembly of cleaned, polished and regrained parts..

Pop Bumpers are rebuilt with new parts. No short cuts on any games..

Regardless of the machine or the value of the machine, I follow exactly the same process as a base standard. For those that have not played a fully working game, it is a VERY underrated machine !