IT WORKS !

Big Yaaaaay !

Of course I have several other plans going in my head, but most of them are additional attachments and a couple upgrades so I'll let you know how those go in their own threads.

The new controls are great! The bucket controls are not only easier to work now, but it also solved my dropping bucket problem! With the old valve the bucket would drop probably 6 inches in one minute (“yow!“). I didn't know whether it was cylinder seals or a valve problem, so now I guess I know. It's been out there with the bucket and auger hanging off it for over 10 minutes and it hasn't dropped even 1/8”. That's better than I hoped.

And I tested the auger out. I'm happy to report that it worked fantastic for the little test I gave it. The soil I tested is not dry, not packed tight, and not heavy clay so it certainly wasn't any kind of extreme test. There weren't any roots or rocks that I could see either and of course encountering those will be inevitable and a better test as well. But I got it spinning, lowered it into the dirt and it just drove right in and didn't show any signs of straining while lifting the dirt up. I know that doing the same with a human-powered post hole digger would have taken me 20 minutes minimum and this auger just took

seconds to go 4 feet deep. Most excellent in my opinion.

It does spin somewhere close to 2 times per second, which is probably a little bit fast. If a harder test shows that it's a little weaker than I'd like then there's a post hole digger gear reducer I saw, which give about a 3:1 reduction, which ought to tweak that down just about perfect to get me more torque. I won't count on needing that though until and unless it actually falls short in practice. It might just turn out to be fine. After all, in my case I probably won't be augering any larger than the 8“ one that is on it already so it doesn't need as much torque as some.

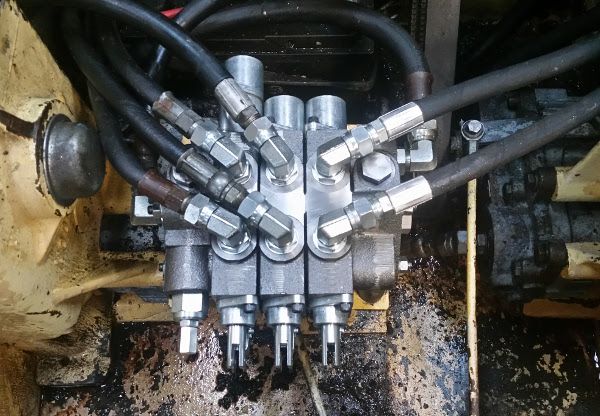

The valve is properly mounted but the aux lines are just bubble-gummed in place right now. I'll do a proper job of it soon.

The ball ends on the old linkages were worn pretty bad and they are cheap from McMaster, so I bought all new ones to replace them. It ought to be nice with the ends all tight.

I got to test the machine before I dug into the new valve and it was plenty adequate to lift the back of the machine right up as I tried to lift a big tree trunk onto a trailer. Two men standing on the back on the second attempt was enough to keep it down and I got the trunk loaded. So I guess since it's strong enough to still lift a load with the auxiliary weight plates attached plus two dudes, at least the hydraulics aren't weak. Good test. Yaaay!

I know I shooda painted the valve before installing it, but I didn't want to contaminate the innards. I'll paint the machine someday anyway, so I'll get a coat on it at that time. Seems to be enough oil all over the thing to keep rust at bay anyway, at least until I fix that (which I will).

I should be able to test the auger in the next couple days.

This thing is definitely a money pit, but it sure is fun. Still cheaper than Vegas, hehe.

Here's a couple snapshots as of a couple minutes ago. Nothing all that illuminating, but at least it's evidence that I got it re-assembled. You can see my temporary auxiliary hydraulics control lever sticking out under the right side of the seat if you look close. I'm going to make it a foot control eventually.

Here it is after poking a 4-foot-deep hole into the dirt. Sorry I drove it back into the driveway after, but I'm sure I'll snap some more interesting pics when the opportunity arises.

One down, dozen to go.