It has been a long time since I did a thread like this, and I wanted to share my experience with Ultrasonic cleaners. The reason I looked at doing this, was because of the manual labour - the HOURS to clean and polish parts. The process I'm about to document, saves me HOURS - literally.

The Utrasonic I purchased is a Chinese branded 30L Utrasonic cleaner I bought off eBay. Cost me around $400. The "original" Ultrasonic cleaners that are the same size, but 4 times the price, are probably made in the same factory...

Off the bat - Do your research. The unit has a capacity of 30 Liters, but the bin, is smaller. The reason is simple, NOTHING you are cleaning can touch the sides or the bottom. Think of a Fish and Chip Shop - they don't drop the chips in the oil, they drop them in a bin.

They are NOISY. VERY NOISY. Even if you have a garage, you will still here it in the house.

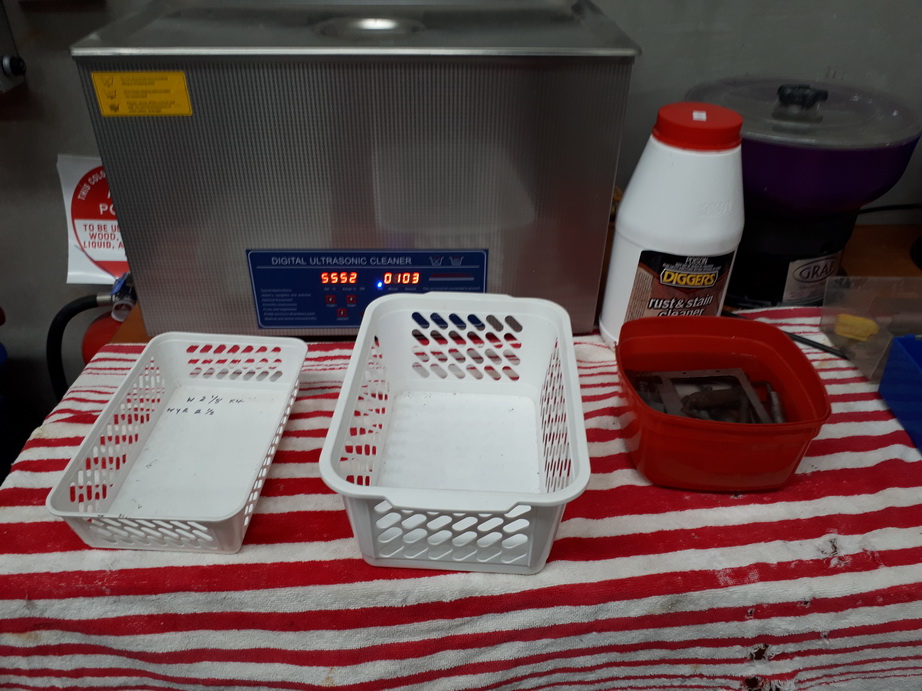

Ok - so below is the Ultrasonic Cleaner, set up on a bench, in the furthermost corner of the Factory.

"FX Degreaser" is the cleaning agent. You need a cleaning agent. This is a FANTASTIC "multi purpose" cleaner. It is EXPENSIVE, but with trial and error, you don't need to use 20% as your solution. I use 200-400ml per machine. I'll get to that later.

Here's the solution mixed into tap water. The water level is OVER the bin (The photo below is before I added more water). You ran the Ultrasonic cleaner for 5-10 minutes BEFORE you start the first cycle. The temperature will start off around 25-32c. After an initial cleaning cycle, it will increase by 5 Degrees.

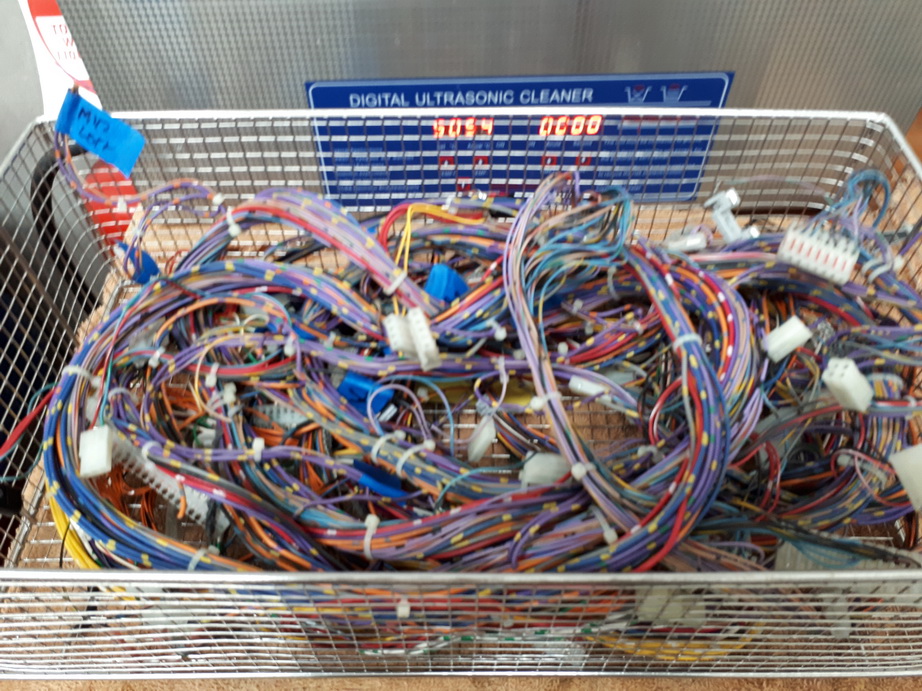

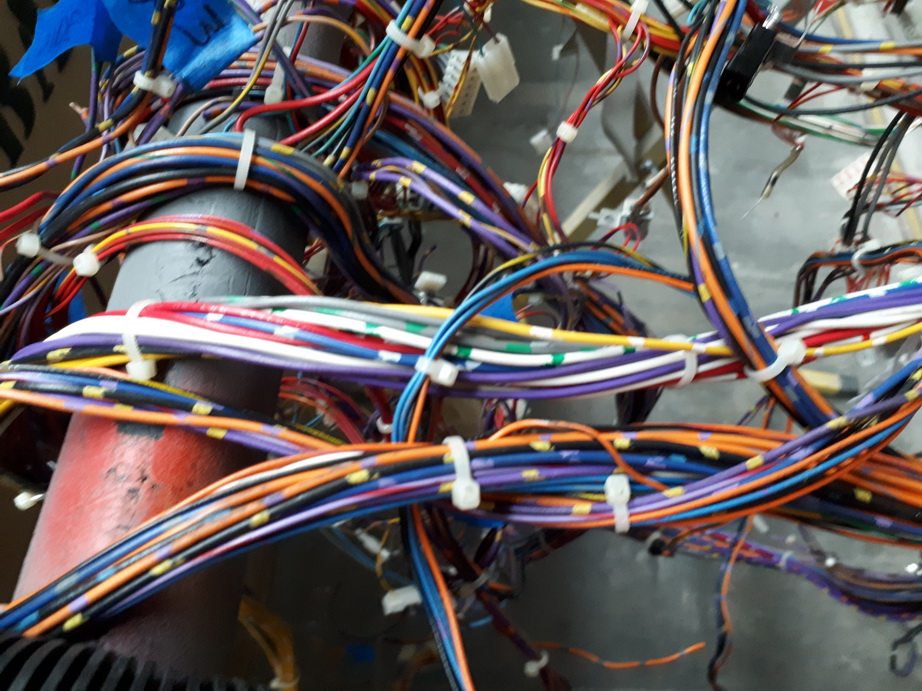

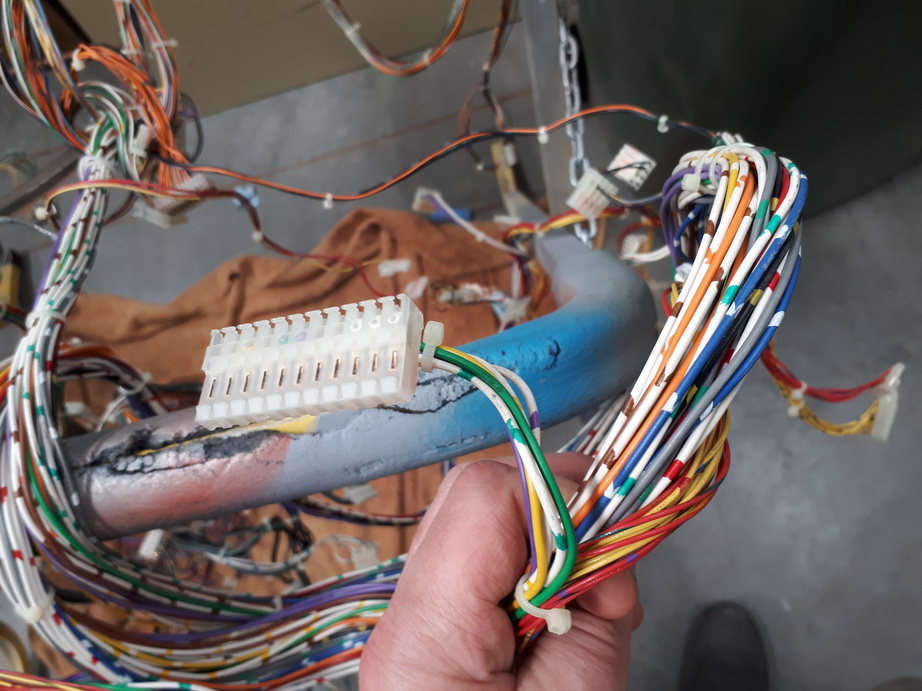

For the First cycle, I will be cleaning one of the WPC wiring harnesses. I do plastics and wiring harnesses first, as when the Ultrasonic is cleaning metals with grease, filth and corrosion, it needs to be around 50 Degrees to work effectively.

I've weighed down the harness with some heavy items that were clean to begin with.

I've set the cycle for 30 minutes - thats all you need. The water is around 20% - the heater is "off" - I never use the heater.

After the first cycle, the temp is already at 54 degrees - that's ok, as most of the time it was less. Perfect for a wiring harness. I remove the bin..

IMMEDIATELY - Drop the bin in clean water. Rinse and place out in the sun. Use a compresser to blow out any water in the connectors and globe sockets..

It now looks like a new wiring harness..

We are only just warming up..

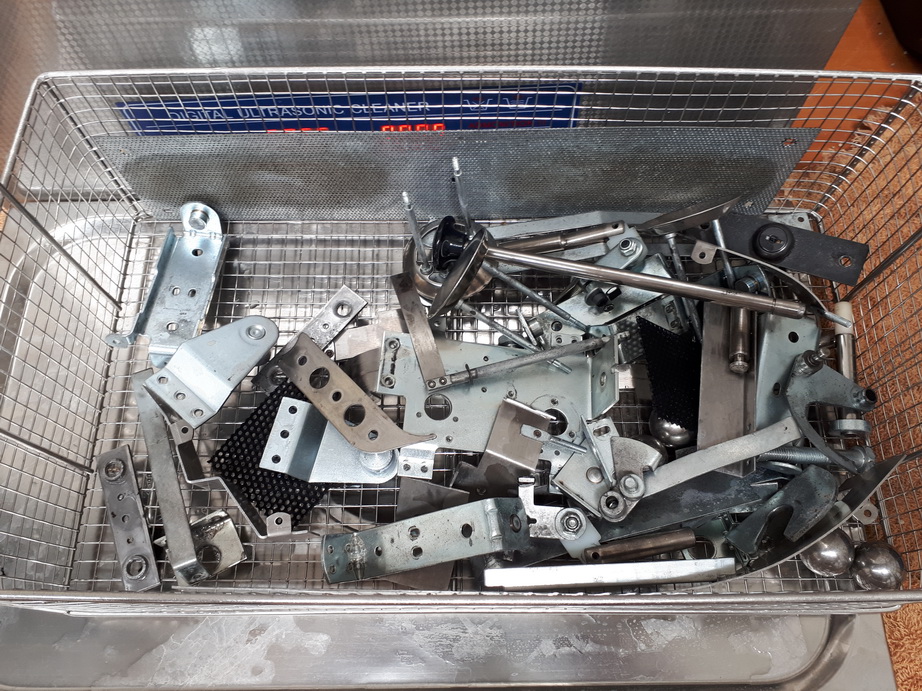

Next we do mechs. Disassemble and separate the really bad parts that need extra degreasing, and parts that are rusted or corroded..

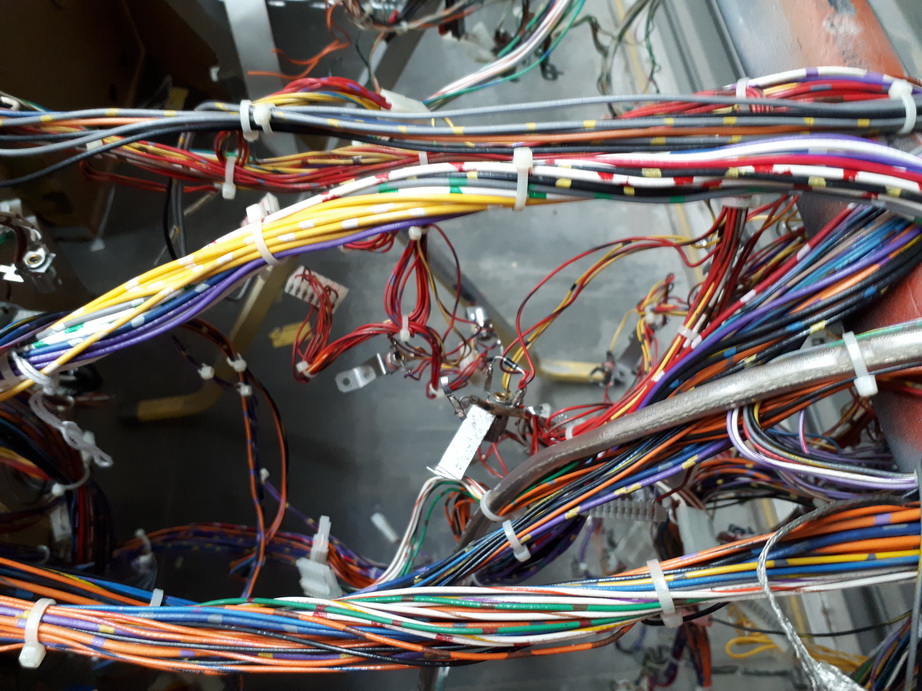

This is where the research pays off. You need to know how an Ultrasonic cleaner works. It is soundwaves that with the help of a cleaning agent, clean parts at a molecular level. The sound travels through the water. So you can have several different "baths" in the one Ultrasonic cleaner. You can put smaller parts in smaller bins. Enclosed bins with different cleaners. In the picture below, I have different bins for different cleaning purposes ;

Parts can be placed in the white bins, and in the red bin, I have the rust remover in a water solution. Usually, I would leave this overnight, but in an Ultrasonic cleaner, it takes 30 minutes.

In the photo below, I have the same solution that cleaned the 3 wiring looms. It contains the usual parts - plastics and metal. The bin on the left, has parts that have stubborn grease or filth, so there is more cleaning agent, and I will remove this solution and disgard it, as it will contaminate the main solution. On the right, I have the rust solution, separate from the main solution. The soundwaves will pass through the container, and clean the rust in the same method as the rest of the parts. I will disgard this solution at the end of the cycle. So I' m doing 3 jobs at once, without lifting a finger !

Heres the filthy metal parts after a cycle. They look new !

Smaller parts in another bin ;

A random tool that was something you would ordinary throw away.

After the metal parts are clean, they go through two different tumblers, with two different media.

If anyone has questions - fire away ! This $400 investment has saved me hours, and $ on parts that you would ordinary throw away !