This is a more recent restoration that I have started. I've never played a Superman, so having one in for restoration was always going to be interesting. The game was delivered to my doorstep by a friendly ex operator who warned me that the game "is a bit whiffy". Not exactly North Queensland Possum poo whiffy, but close enough for me to leave the factory roller door open for the day while it was fumigated outside !

Initially, I thought it was in very poor condition. A lot of rust, filth and an outstanding eviction notice for the rats and spiders was pending. The cabinet can be restored. The backglass needs a replacement. The playfield it outside of my skillset, so I sent some photos to Tim at HRP, and he was just as excited as I was to take on the project.

Another joint HRP & APR High end Restoration was already in motion !

Condition reportCabinet 4/10 - BADLY needs a repaint. Side rails and lock down bar are rusted. Jeff at Rail-Ways has already provided us with a set of new siderails. Gav has already done the Cab stencils, so we are off to a good start.

Backglass - 3/10 - Poor. Needs to be replaced. Colours faded and peeling. This will be a challenge

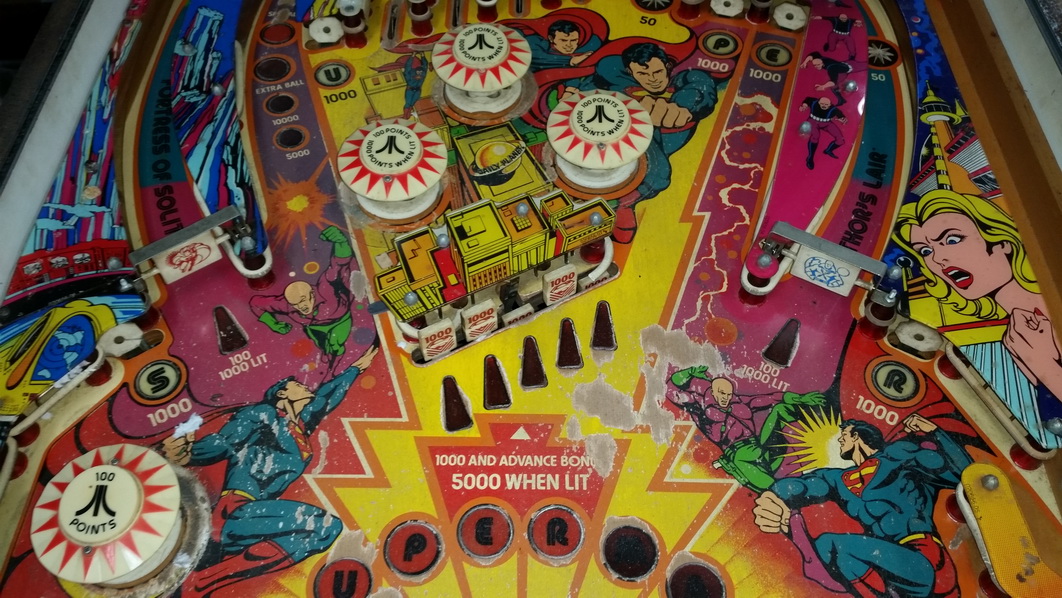

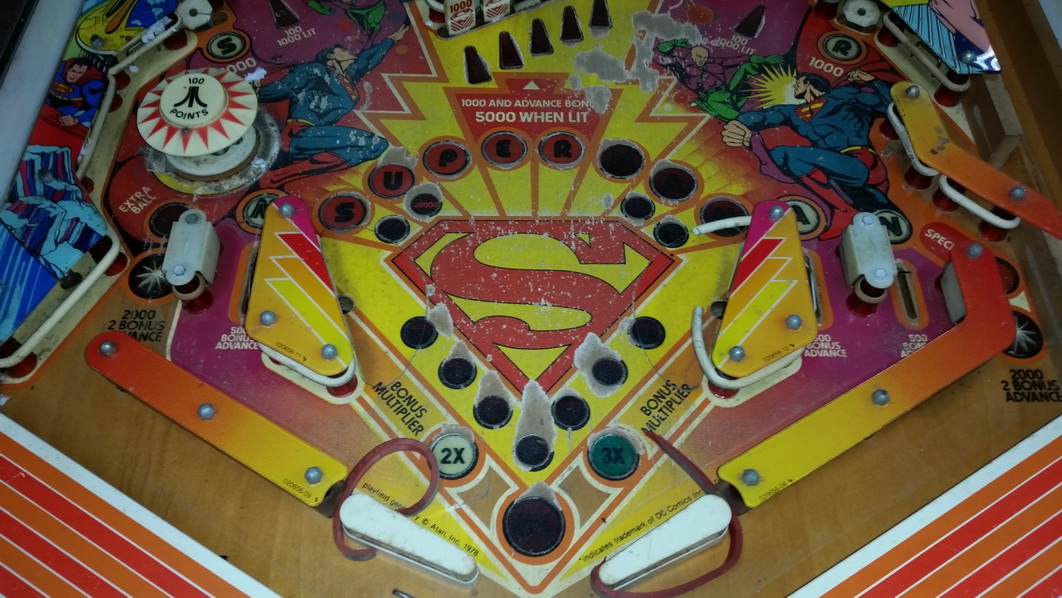

Playfield - 3/10 - BAD. Lots of wear. No mylar or contact. This kind of detailed work falls neatly into Tim's lap

Electronics - Unknown. I did not attempt to power up. Power cable was cut.

Initial Presentation

Front door will be restored as per original finish. Notice Aussie delivered game. The shooter assembly appears to be Gottleib parts.

The "bad" side of the headbox

Will be using Gavin's stencils for this project. We have found that other Stencil manufacturers are not even close to the quality and accuracy.

Playfield

I think the playfield presents a challenge, but I don't think it will present to many issues for Tim. Just time consuming. There may be a separate thread for the playfield restoration.

Inside the coin box area - Very smelly

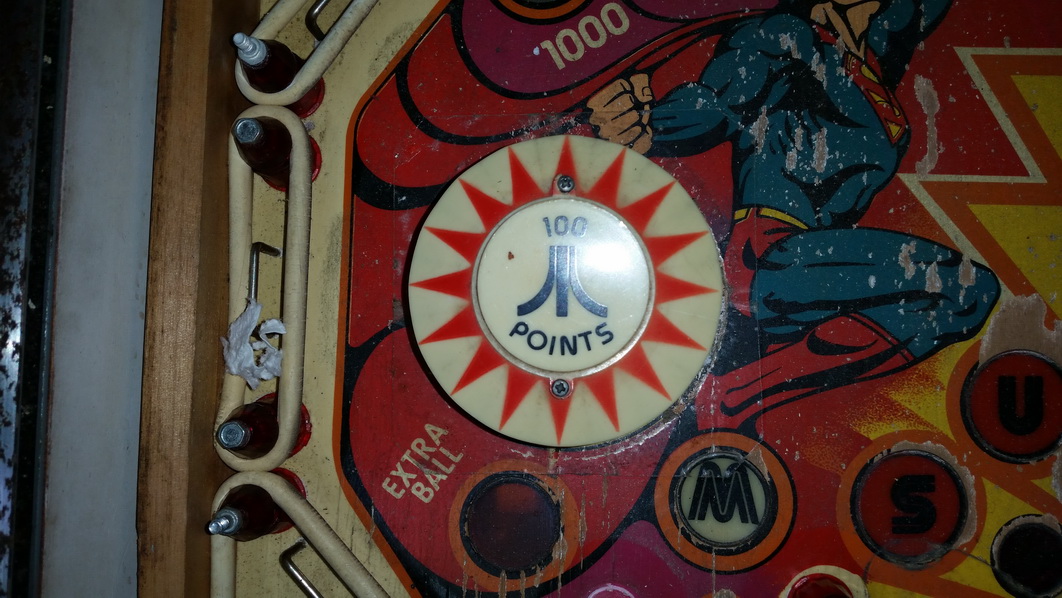

I've seen some VERY strange anomalies over the journey, but a pop rivet in a playfield is certainly interesting !

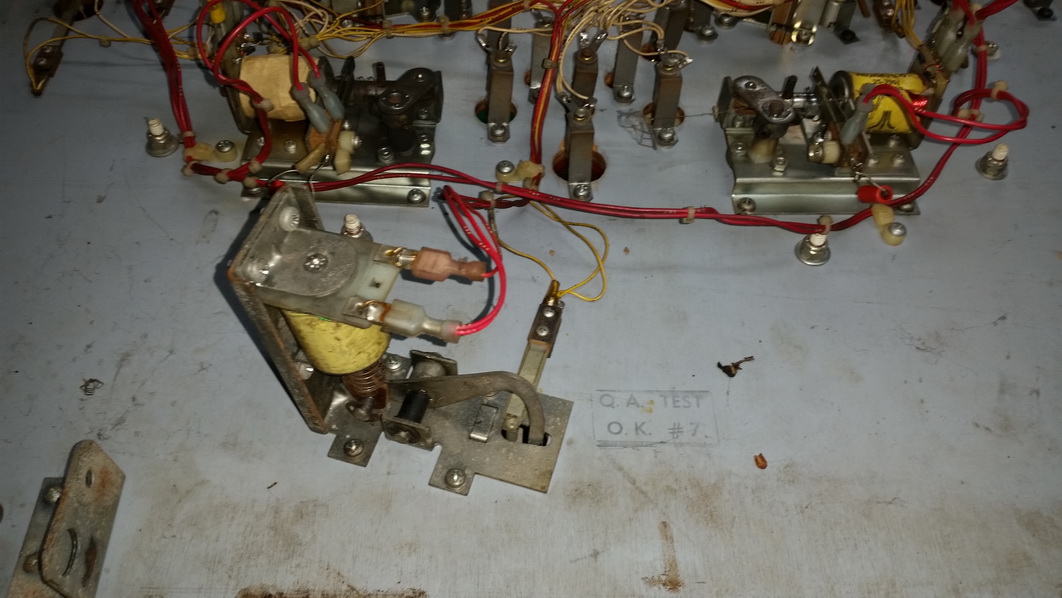

I've learnt that Atari approached pinball manufacturing much like their video game cabinet construction. Everything can be disassembled without desoldering.

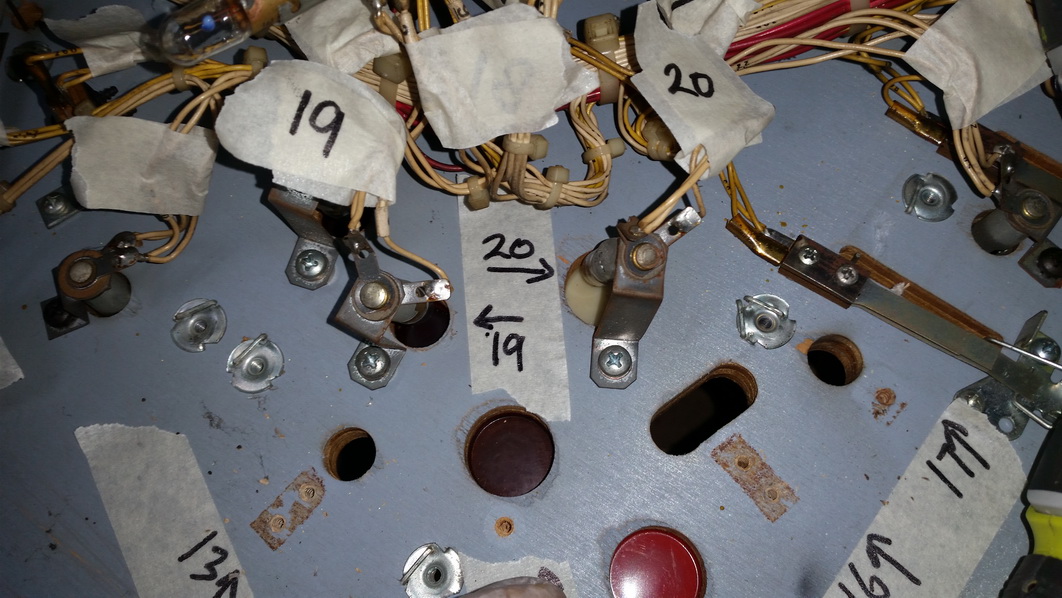

When disassembling playfields, I use a system whereby every single item is noted. First I use a simple numbering system to identify each individual playfield part - switches, lamps and assemblies. I label the component on the wiring loom, and also the area on the playfield that the part is located. When all the components are removed, I take photos of the blank playfield. Eventually, during the process of restoration, the playfield underside will be cleaned and refinished, but I have a record of what goes where once I have the restored playfield returned.

Stripped playfield ready to drop off to Tim at HRP

Next stage is to match the colours for the repaint of the cabinet