Over thanksgiving weekend; I worked extensively on the PF. I started by spraying backside of the PF with grey primer ... unsure why the older Bally PF had the grey paint on the backside... but I figured when in Rome; do as the romans do.

Once the grey primer was dry; Sprayed the inside of the insert holes white; partly due to the Romans... partly due to the desire to have a clean looking insert. Here's the back of the PF trimmed up and sprayed.

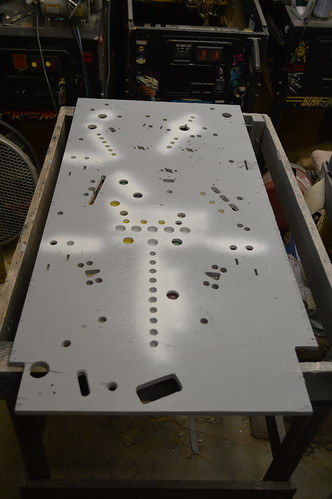

With the white dry; I began gluing in the inserts. Once I had the inserts glued inplace and dry; I took a 80 grit orbital sander to the whole PF to level the inserts and remove the white primer. Here's the PF at 80 grit:

And again at 220grit:

Then I proceeded to sand the inserts to 500 and 800 grit. At this point I considered the PF ready for ClearCoat. For this I used ChromaClear 2part 4:1 automotive clear. I put down one light coat and 3 medium coats. Heres the PF after clearcoat:

I let the clearcoat cure for a little over 24 hours; then sanded it flat with 220grit orbital sander to remove the orange peel and give the inserts another flat process. The PF/inserts needs to be flat so the sign shop can print the insert circles and artwork without any gaps in the art.

Here's the PF being back lit by shop lights:

While I waited for the clear coat to arrive; I received the vinyl decals from Callie Graphics. I went ahead and installed them on the powder coated blanks:

On Friday afternoon; I took the PF and artwork files to Austin Color Labs so they can put the artwork directly on the PF. I hope to hear from them by end of week with a printed PF. When the PF gets back from the printers; my plan it to put 4-6 coats of clear coat over the art then sand flat and polish to a shine.

While I wait for the PF; I'll try to clear coat the decaled apron inserts... if we get a warm day in the near future. In the meantime I have PCBs to assemble; including the ATX PSU board.