There has been a bit of talk lately regarding topcoats and durability on Stern playfields - some positive, some negative.

I think that cleaning and maintaining a waxed playfield would go a long way to ensuring that the playfield finish lasts as long as reasonably possible.

A number of AP members have also used the HRP clear coating service as a way to help protect their playfields. I usually dont comment on costings, but there were a few figures thrown around on another thread which were way off the mark for a NEW/REPRO playfield refinish and clear coat. The figures may not have been related to HRP directly but even still i feel this may be valuable information for people considering a premium clear coat as a way to protect their playfield.

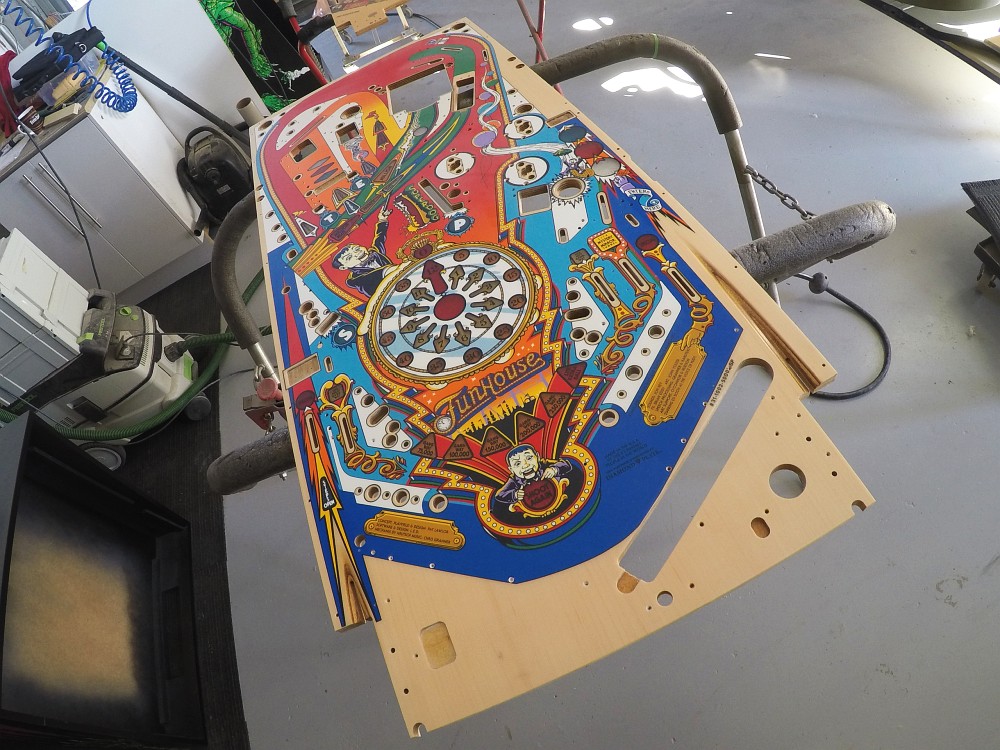

The following job was brought in by a local collector - a spare Stern would have been nice for this case, but we have a repro Funhouse for this example.

As received...

They look nice new dont they...

So the first step in our process is to evaluate what we have - dont get me wrong, im not complaining about the playfields, they are an AWESOME option for collectors looking for an upgrade to their original, often blown out playfield - but we are trying to improve these in every way - even new mass produced ones.

The shooter lane is pretty blonde, the Williams/Bally examples tend to have a darker tone to them so we will add that here...

The clearcoat on the reproductions these days is pretty thick as well - but the problem is they arent sanded flat, de-nibbed and polished out. It simply wouldnt be economically viable for them to do this for every playfield so we will address this. This photo shows the wavy appearance in the centre red clock insert...

Other things like the black bordering is split on the lower clear insert. Again, for a production run this would be acceptable but its easy to get it corrected here on a case-by-case basis...

The playfield is cleaned, and much of the factory topcoat is removed during the prep stage...

At this stage we also smooth up the shooter lanes, they can come in a little jagged at times - again understandable but we can rectify this so its nice and slick...

Shooter lanes are toned up at this point too...

Subtle but does make it look a little nicer with the contrast...

Bordering is corrected and ready to clear...

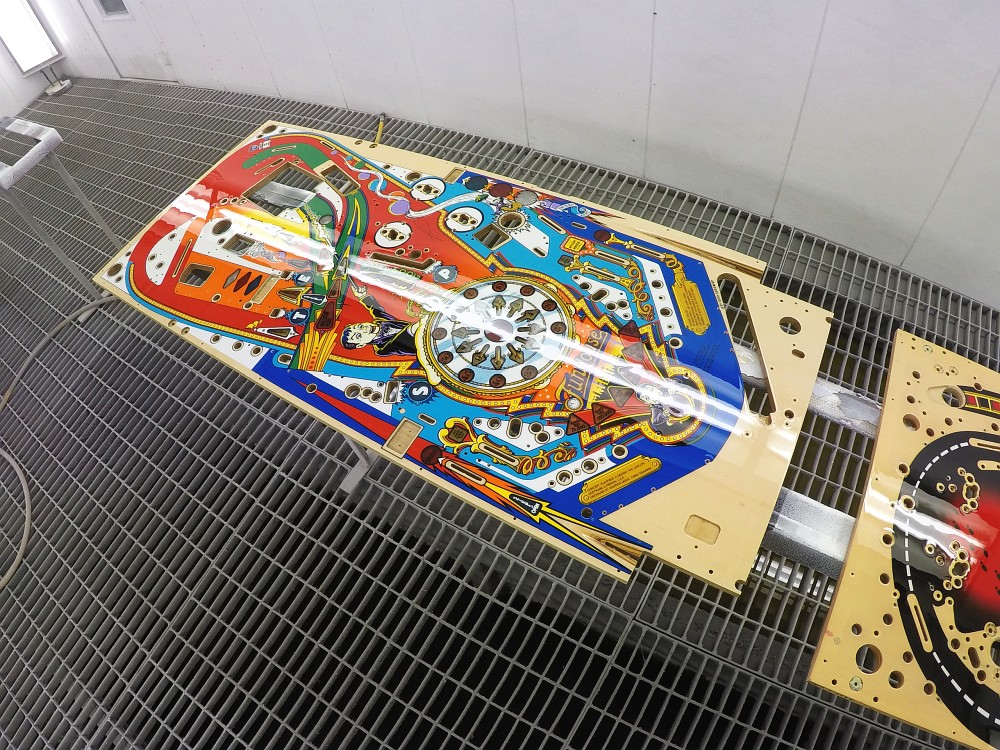

In the booth, cleaned thoroughly and ready to go...

Cleared in this picture. Common question we always receive is 'how many coats of clear do you put on'. People read the walkthroughs and how-to's on this topic and come up with some strange processes and expectations on clear build. Automotive paint is designed to be measured in micron thicknesses - not millimeters. We refer to our clear applications as 'booth sessions'. This particular playfield, and most repro/NOS refinished playfields we do are only in the booth once. How many 'clear coats' that equates to (re Online tutorials) well we cant answer that as each painter is different, some will put it on pretty hot while others will build up their finish gradually...

Details of the above. The clear starts to flow out and level nicely on its own in the right temp/conditions...

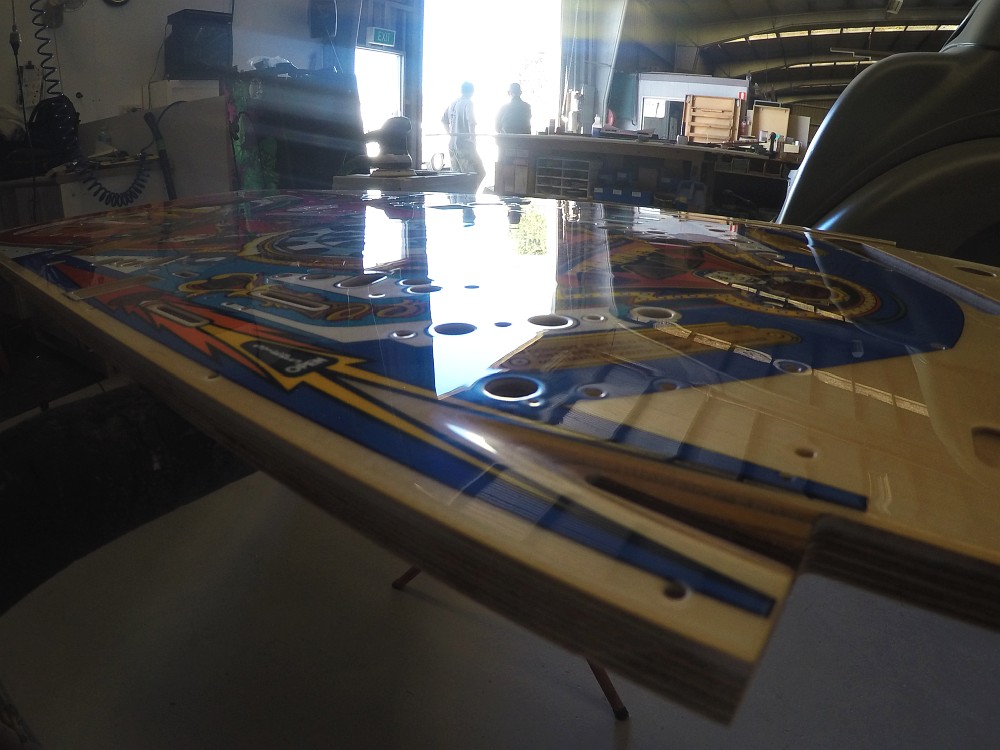

Playfield has been left to cure and we can move to the next stage...

If there are any dust particles that settle on the playfield, which happens - we de-nib them. You can see one here...

And here - but its a bit hard to make out in the photo...

De-nibbed the playfield and it is sanded flat, ready to polish out...

You can see the playfield is dull and lifeless before its polished...

Playfield is polished back to a high gloss, and ready to detail...

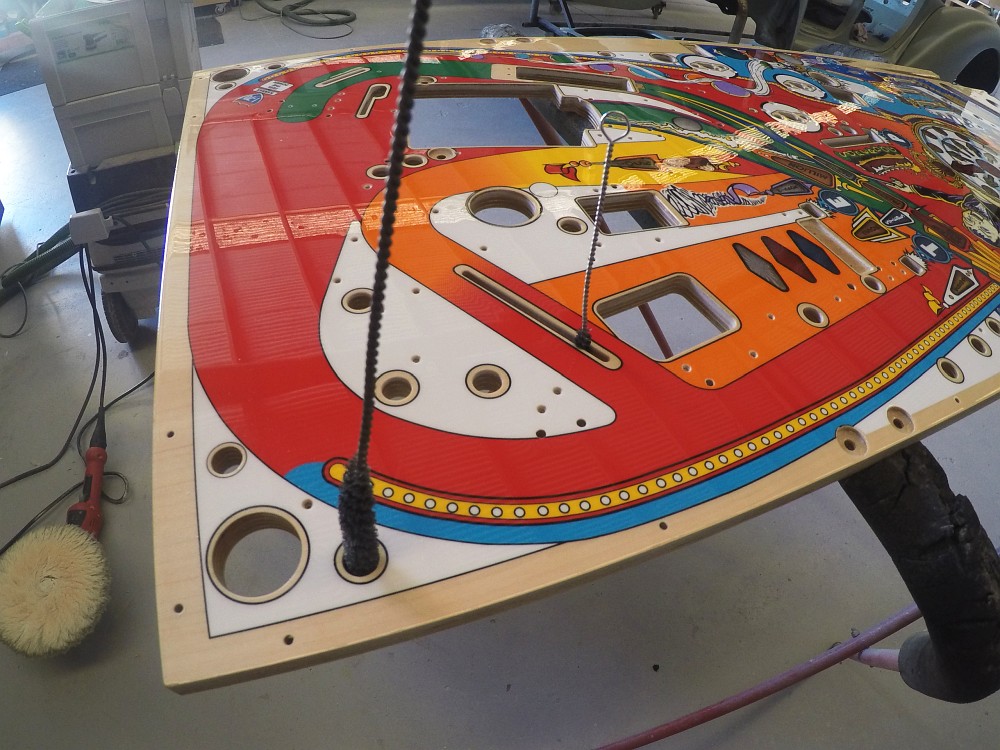

Details...

These wire brushes are used to clean the cutters out of the openings. There isnt HEAPS, but its a pain to do. A dremel is also good in bigger areas...

You want to get it as clean as possible...

Ready to wax...

Wax on...

Wax off...

Photos arent great as it was quite a sunny/bright day and things look a little washed out on camera. Video may help in highlighting the finish...

The total cost of this job was $350.00. Now, this is not a QUOTE for everyone's spare playfields. There have been times when re-clears (like the job documented above) have been slightly less or more but this has been a rough, AVERAGE cost for this process for a while now from HRP. Things like shipping interstate and packaging are obviously not included in the price detailed above, but i hope that explains a bit of the process, and the rough costs associated with such a job.

I am trying to put a bit more up online this year, as i think its a good way to document the projects - many of which are commissioned from AP members. Thanks for your support as always

Tim

HRP