**56K DIAL UP USERS SHOULD NOT LOAD THIS POST - IMAGE INTENSIVE**Hi guys,

It's been a little while between posts for me so i thought i would put up a visual timeline of the development and application of

our replacement WPC cabinet project.

We have been re-using and restoring cabinets for a while now down at the shop, however over the past 12 months there has been an considerable drop in condition and structural integrity evident in recently supplied 'base games' from clients.

While the option to fully restore and repair these old cabinets is always available, we really felt that it was important to have an option to supply a brand new replacement cabinet if the cost to truly repair/restore was going to make moving forward with the project un-realistic.

The following is a very brief look into the developement of the cabinets. I wont go into terrible detail as i will never be able to cover everything so i will rely on the photos to give a thousand words ;)

Every panel that makes up a WPC cabinet is measured and digitalised so it can be CNC cut/routed. After this process the panels come into the shop and they are further machined with the correct joins and angles to replicate an original cabinet in every way.

First panels ready for machining...

Its not until you start documenting the components that you see just how much goes into these cabinets...

Panels have been moved through the first process...

First batch of MM, AFM, MB etc processed...

Heads being assembled...

We felt is was very important to use the locking mitre as per the factory. Its extremely strong and a very clean join :-)

Starting to take shape...

We also wanted to make sure that these cabinets could be produced in batch numbers, without becoming an overwhelming task...

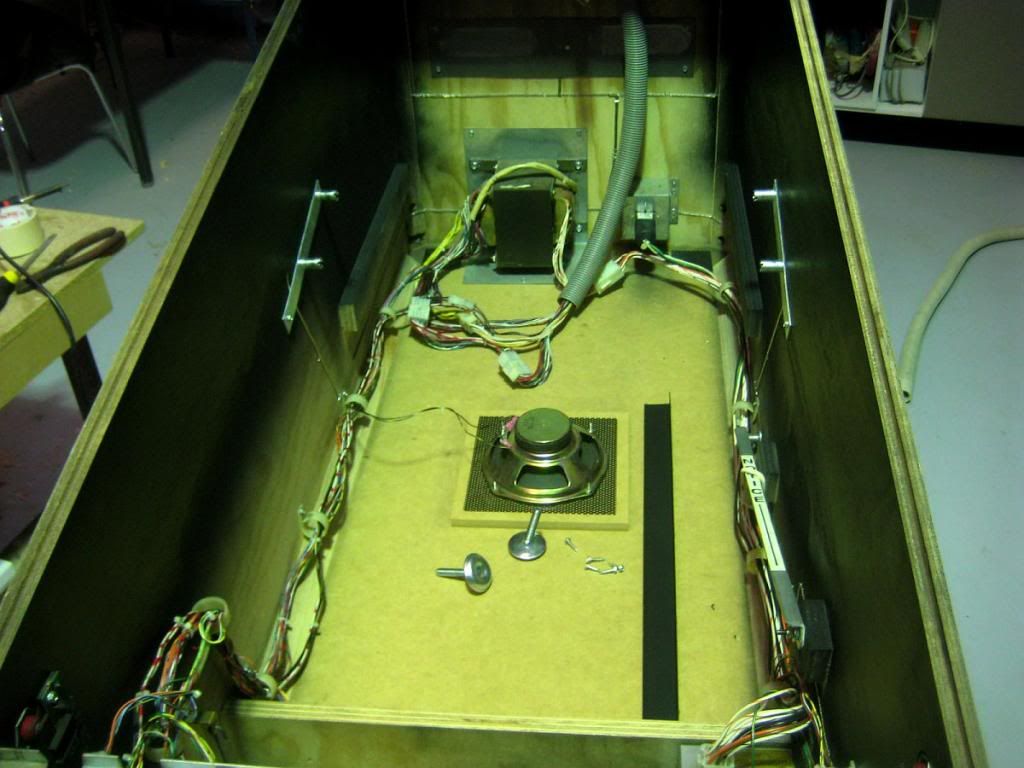

Pictured here without the speaker plates (waiting for mounting hardware)...

The above shows a glimpse of the production process. Below is a great example of how these cabinets really serve their purpose.

Local AP member and admin pinnies4me contacted me regarding an AFM cabinet restore, just as the cabinets were moving out of the prototyping stage. We thought it would be a great opportunity to swap over a complete game and evaluate the results.

Here we go...

Cabinet was able to be completely assembled less the hardware, prior to receiving the base game.

Backbox as required...

Pictured below is the new AFM cabinet waiting for hardware...

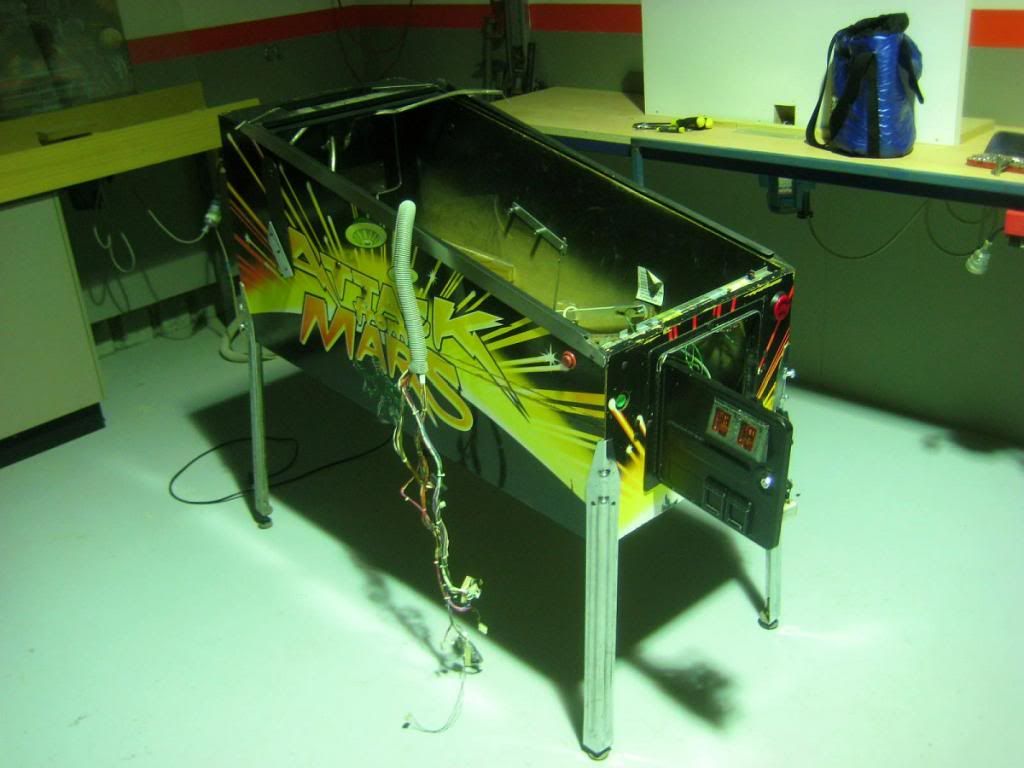

Nicks AFM as received...

The game probably ISNT the best candidate for a completely new cabinet but it does have its fair share of issues.

The rear...

Some fairly significant gouges...

Playfield ready to remove...

Old head stripped and set aside...

lower nearly stripped...

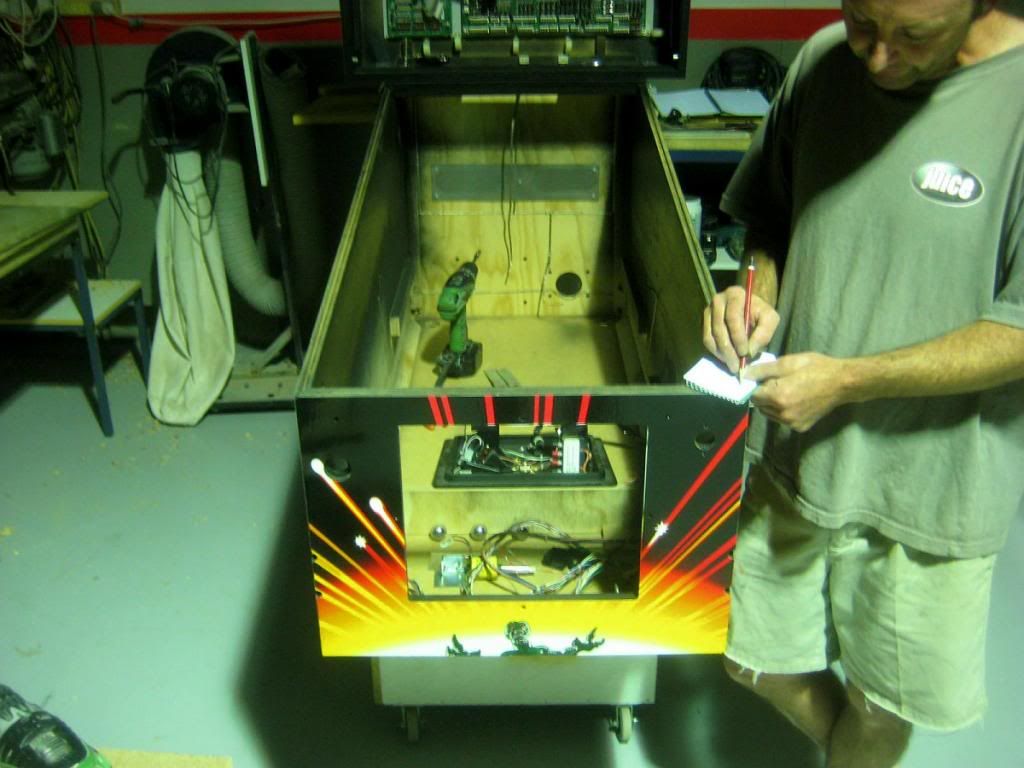

Pinnies requested a few extras, Stuart pictured here documenting the options...

Ground braid installed and run neatly...

Installing the boardset in the new cabinet...

Wired and powered...

Just testing the fit of the cabinet...

Wiring will be neatened up but is just installed for now...

Most harware installed here...

Playfield installed...

Chrome trim and hardware was requested, plating returns and will be installed...

Up on legs and will be moved to the other shop to be dialled in and checked over...

Back at the assembly shop, cleaned and ready for final photos...

The following are simply the tried and true glamour shots :-) Just to give a good overview of the finished project.

Here they are, and thanks for reading. I should also mention that these cabinets are not being built exclusively for HRP (we really did need them though), if you have a need for a replacement WPC cabinet simply shoot me a PM or get in touch with my via the website.

We didnt touch the playfield, but Pinnies did a great job ;-) The mirror blades look great too Swinks ;)

Thanks again guys,

Timbo