I am a bit behind on my restorations, but here's a game I've recently started. One of my favorite SYS1 Machines that is popular with collections, but does not receive the same recognition as Joker Poker or Genie (Genie is also on the floor for a restoration). It is being restored for a Collector on AP, and it is a game I imported several years ago. As with most of my games, it was "hand picked" and is in very good condition to start with.

Condition ReportCabinet - 8/10 - Typical fade, but no structural issues. Very pleased with the cabinet. Backglass is the best I've seen on a Sinbad. They are always either severely faded, or have paint lift/cracking.

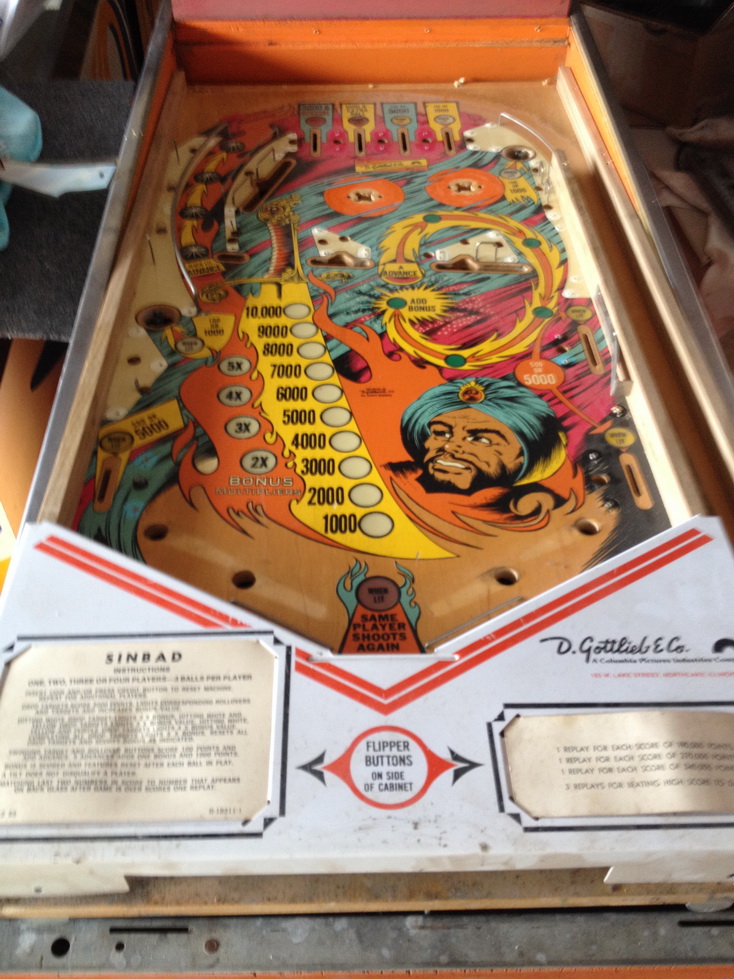

Playfield - 8/10 - Dirty. No planking, but lots of ball swirl. Minimal Insert wear. Hardy any wear at all except a small section in front of the flippers

Electrical / Electronic - 8/10 - Boards won't be an issue. A PASCAL 4 in 1 has arrived and will be installed. Lots of re pinning, but no board repairs.

BEFORE picturesA VERY solid base for a restoration

Stunning backglass - Best I've seen on a Sinbad

Teardown and cabinet cleaning

Teardown and cabinet cleaningThe playfield is disassembled very quickly.

Filthy lower cabinet

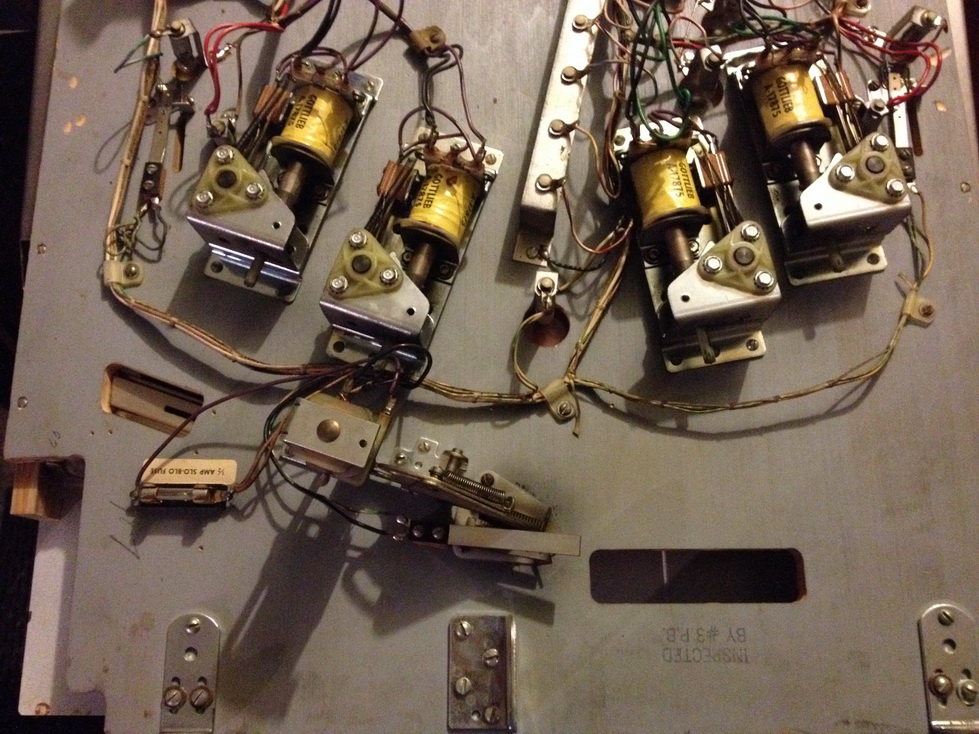

Flippers look to be in reasonable condition. But they will have flipper kits installed so they work perfectly.

Cabinet is vacuumed and cleaned from top to bottom

All mechanisms will be rebuilt

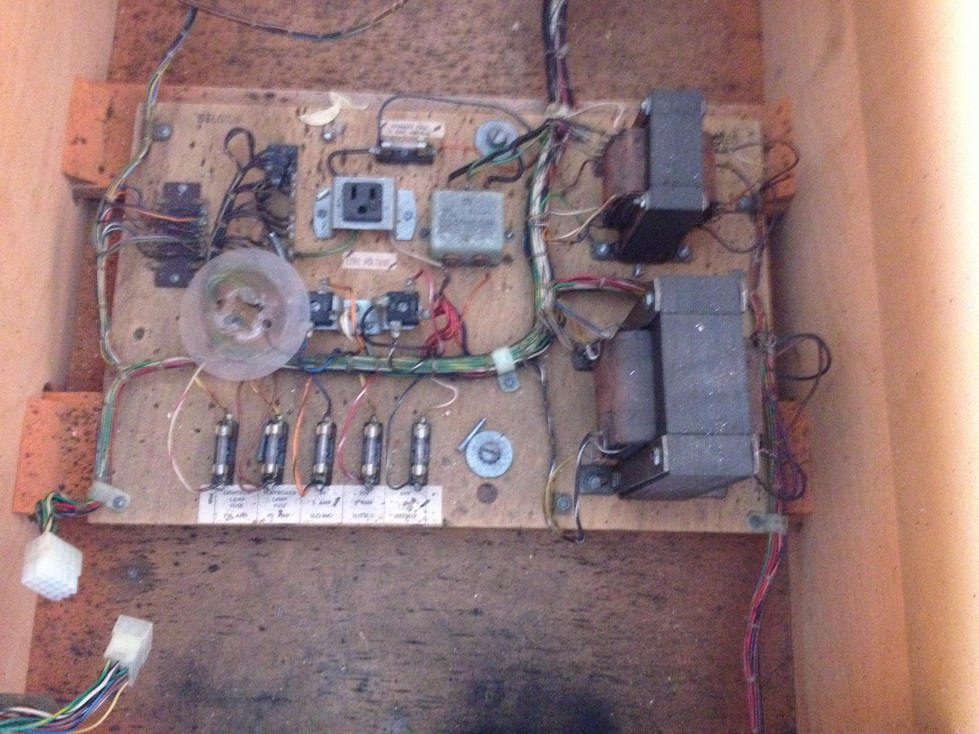

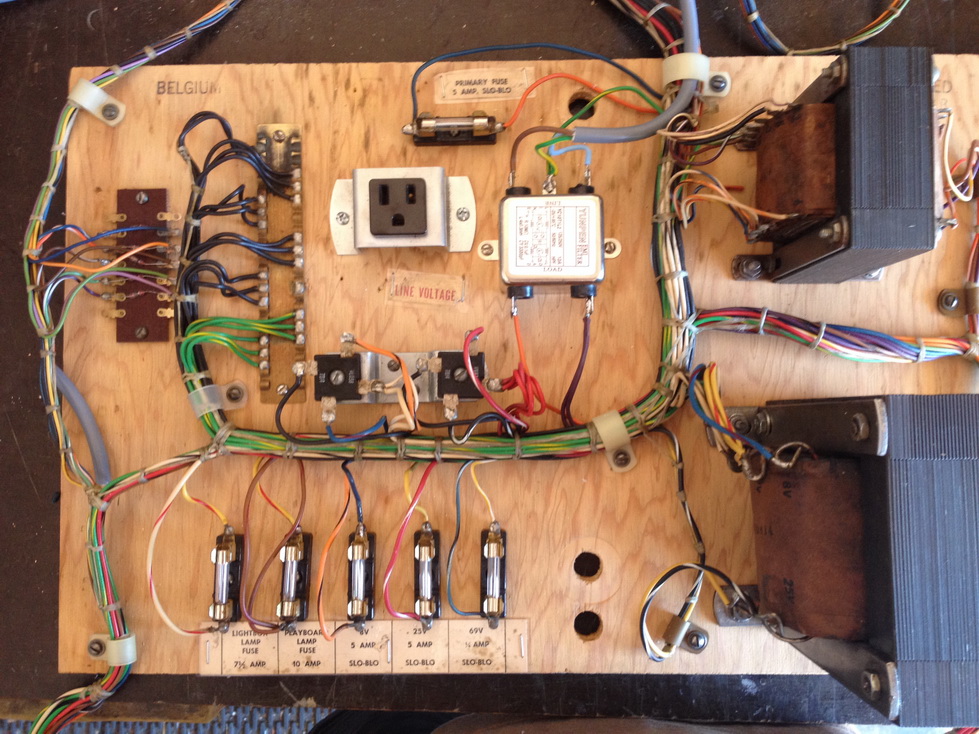

Transformer Board

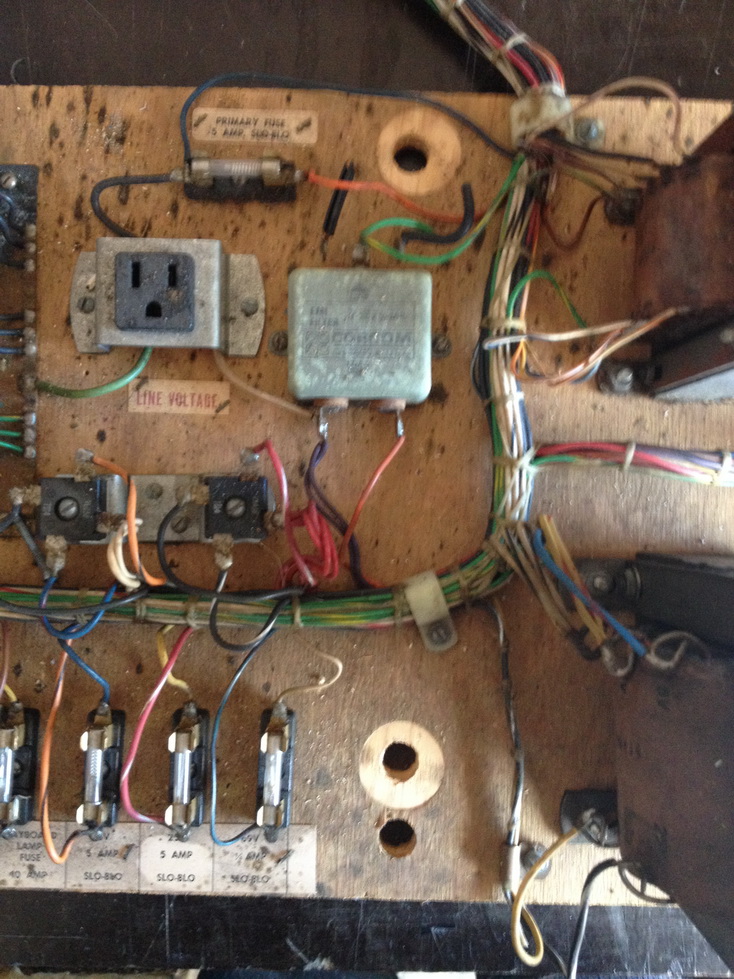

I get asked a lot about the power train for SS machines that are bought as "projects", and the re-configuration to Australian standards. I ALWAYS replace the EMI Filter on ALL SS games - regardless of their country of origin. Fuse holders are checked and I discard old fuses. New power cable is installed. I remove the wiring to the service outlet. Here's the process in pictures ;

The original Transformer board

The old EMI Filter and service outlet

I remove all components and check everything. I then clean all the parts and the bottom panel. I laminate any reference cards

Finished transformer board. All that is left is to test the output voltages and check the connectors.

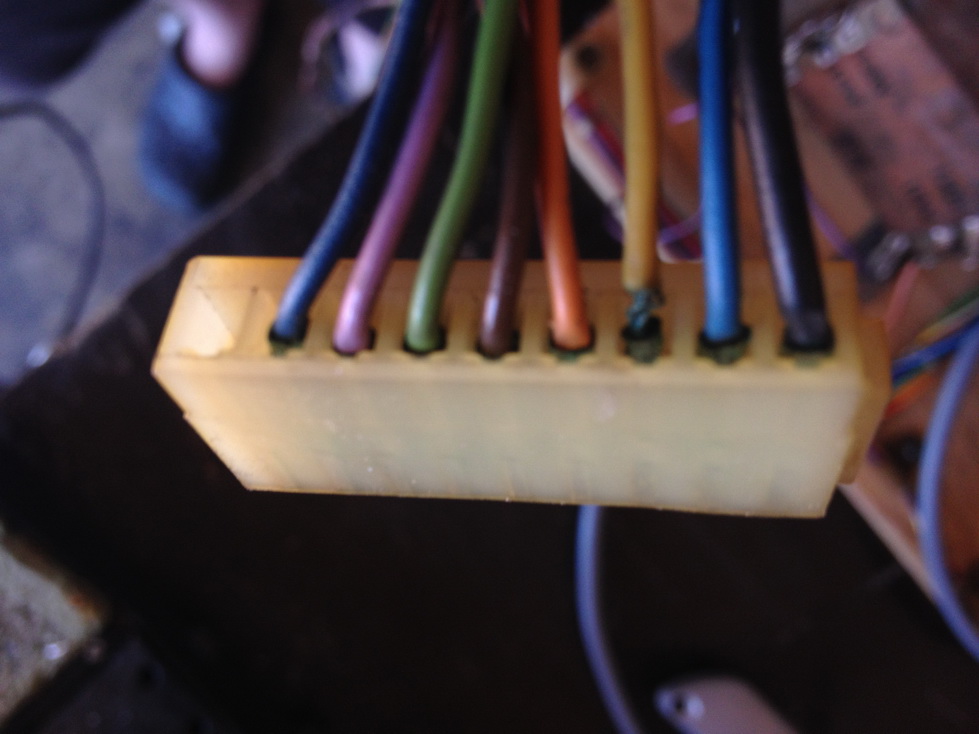

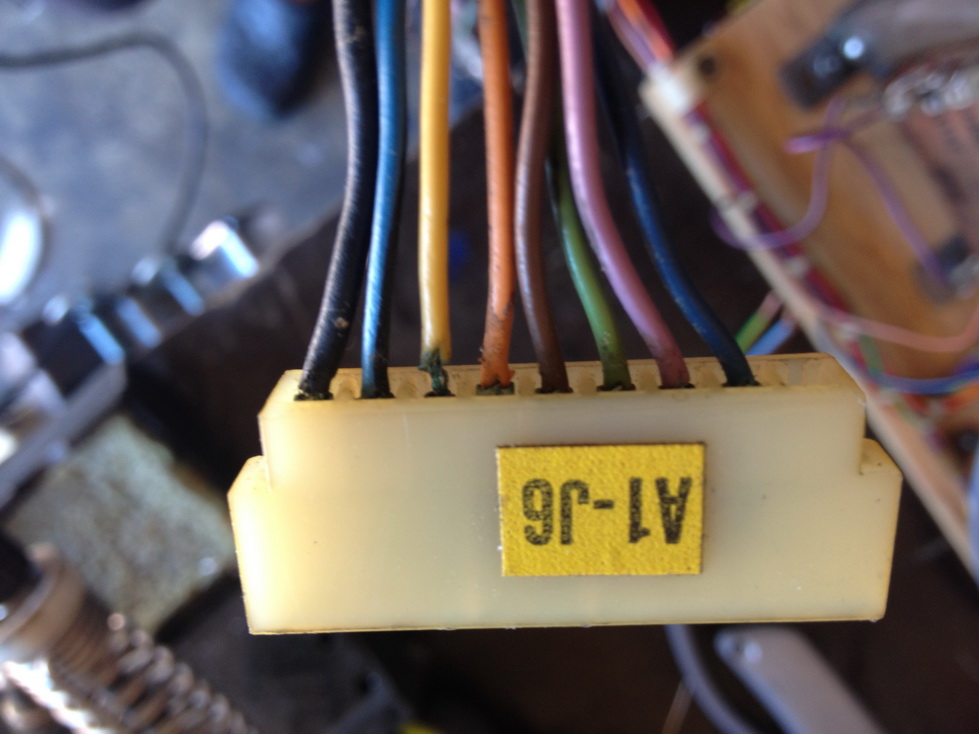

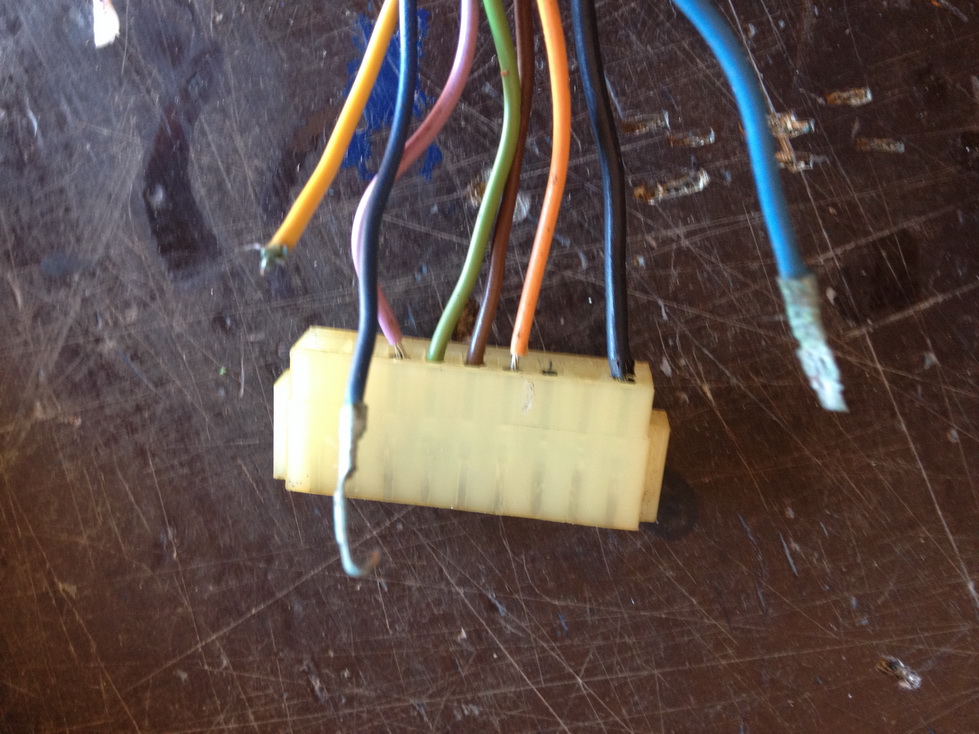

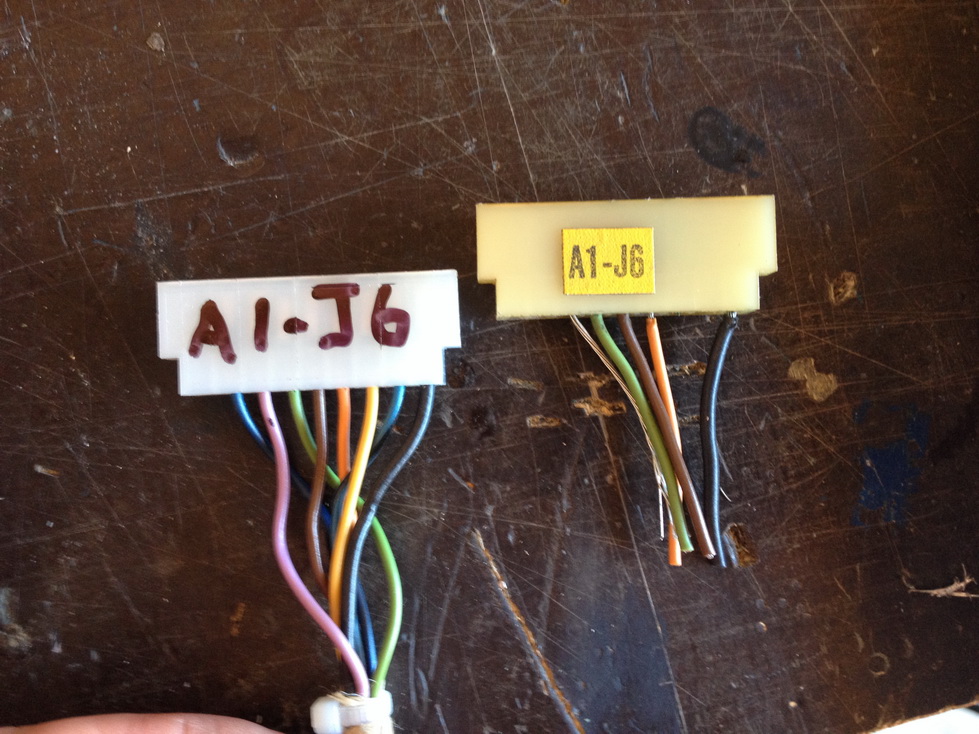

Straight away I know there is a lot to do with the connectors, without even looking at the boards. Corrosion and broken pins need to be addressed. The trend is to replace only the visibly broken or corroded pins, but once I see a couple of pins, then all pins have to be done. In some cases, I replace the entire connector.

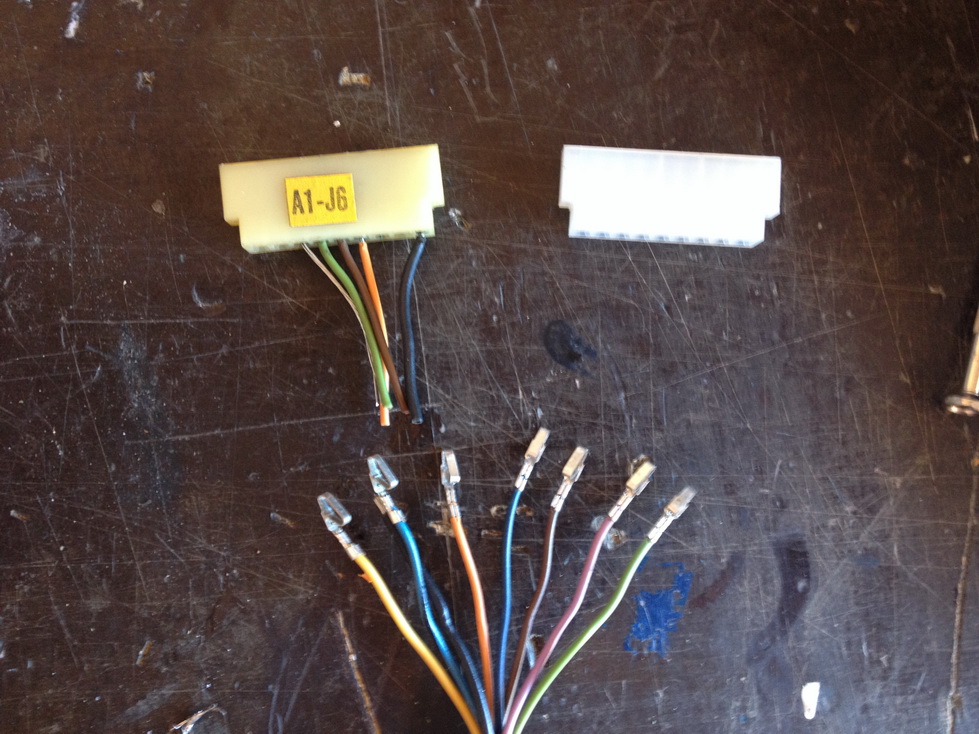

In the pictures below, there's only ONE affected pin - The YELLOW wire. Right ?

On further inspection, the next two I pulled out were broken. Not visible until I removed them

ALL pins are replaced

This process will most likely have to be done to all connectors !