The most IMPORTANT First Step is the understanding that this process has a difficult learning curve. You need patience. You need to allocate time where you will not be distracted. Once you decide to try plating, you will most likely start with a small 4L Kit, as you will need the power supply, anodes and everything else to get started. From that point on, you can just buy the refill kits.

The single most important part of the kit is the instruction book. EVERYTHING you need to know is in this book. I have only needed to call Janeskits ONCE for advice, and that advise was in the book anyway. If your the kind of person that won't read manuals, skip plating. You are wasting your money.

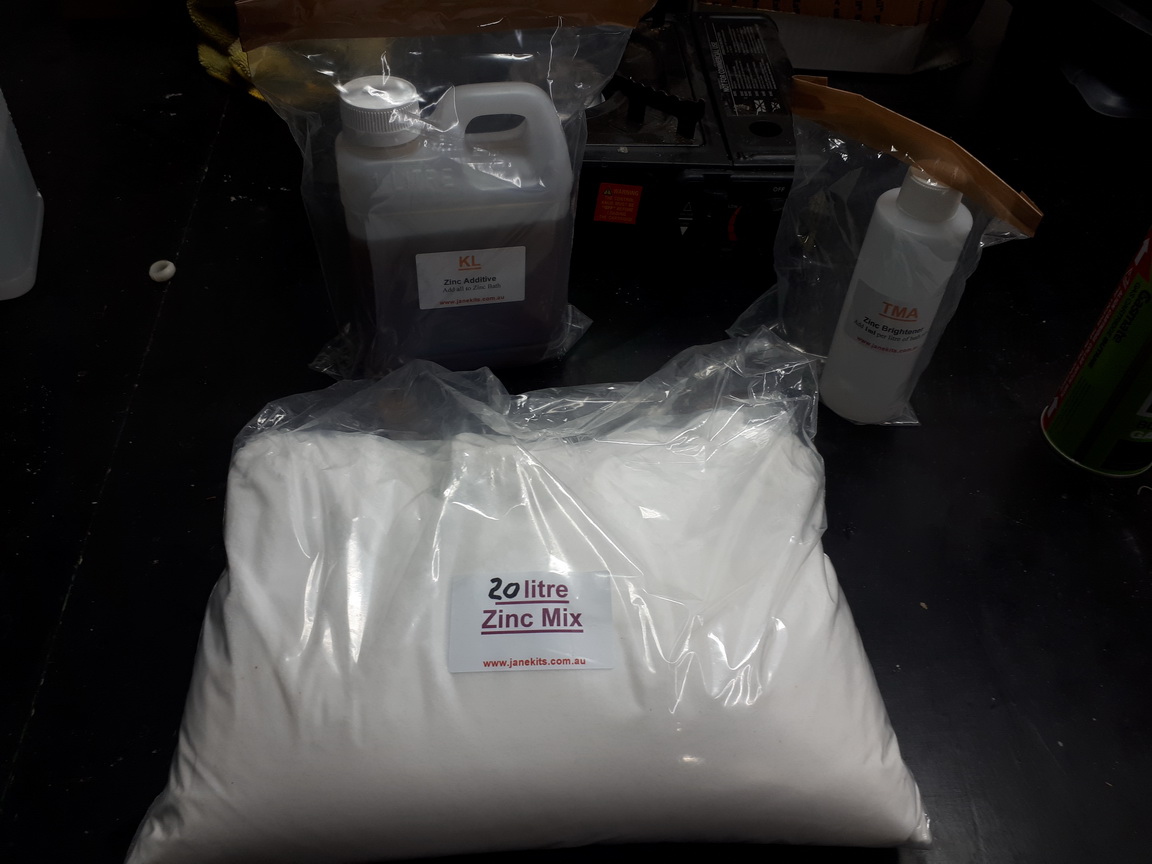

As part of the 20L Refill Kit, I have the Zinc Mix (powder), TMA Additive and Brightner. This is the magic potion. Just Add Distrilled water, or rain water.

This is a 20L plastic Bath. I use a number of tubs for different parts - long parts, heavy parts, smaller parts - but I mix the 20L kit in this tub.

Rainwater. Don't use tap water for the magic potion. It has chemicals which will react and cause issues with the bath. Plating will be erratic.

Agitator - Not required for small baths. This keeps the magic potion running around over the parts. sometimes sediments rest on top of parts while plating. The agitator moves them off.

The Magic Potion - as I like to call it.

The Power Supply - Just a basic unit that can deliver 2-3Amps to the bath.

Basic Gas Stove - of the Camping variety.. BEST plating results are achieved at 27C and above. So I "Cook the Pasta" to bring it up to temperature.

Chemical - Rust and Scale Remover - This is used to remove plating AND remove corrosion and rust. It is diluted with water and placed in its own tub.

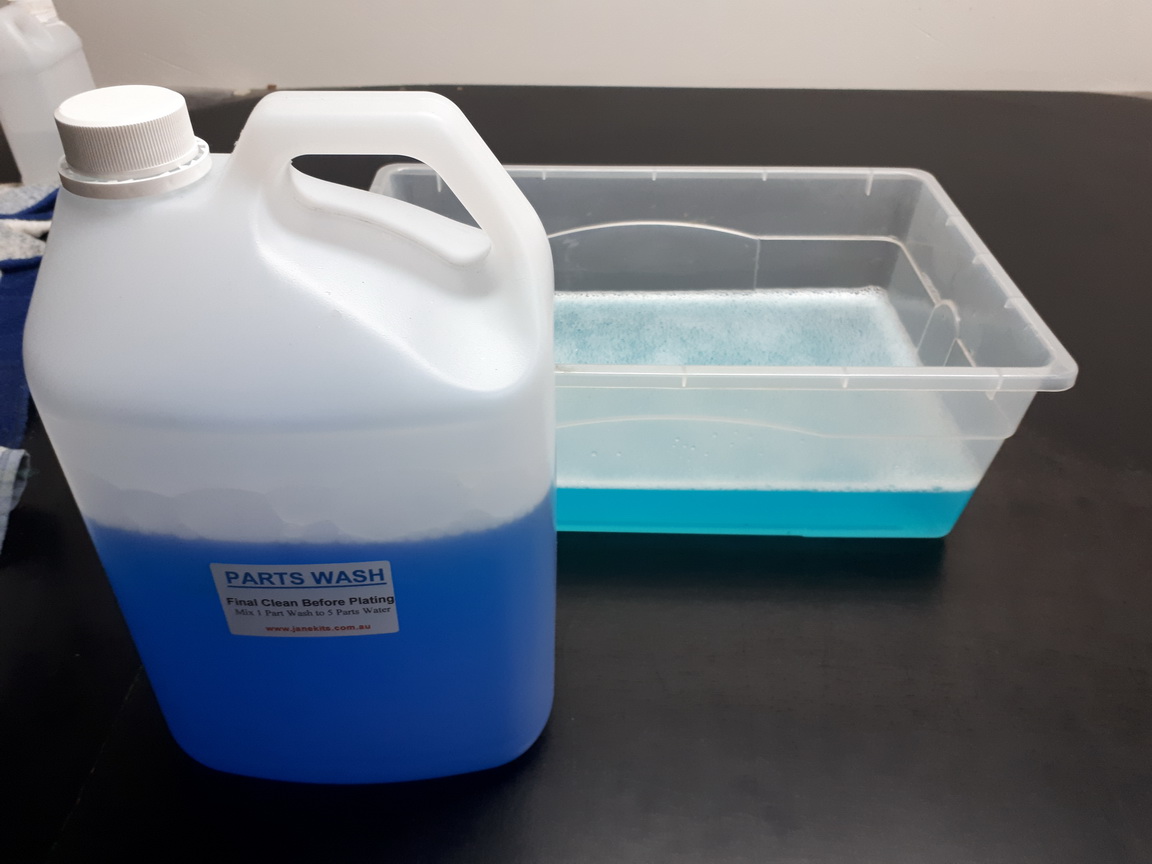

Chemical - Parts Wash - Used as the last part of the preparation, after Rust etc have been removed

The Setup - This is why you need HEAPS of room..

Left Container = "Pickle" - I'll cover that later, but it is Hydrochloric Acid and water - removed old plating.Next Container - Rust and Scale Remover - For removing Rust / CorrosionNext Container - Water. To wash off contaminants before placing in the last containerLast Container - Parts Wash - This removes grease, oil, and preps the part for plating.

That's the basic setup. I'll update the next part soon. In the meantime, here are more examples of zinc plated parts ;

Feel Free to ask questions