This restore was documented on InventForums, so I thought I'd bring it across to AP just as a reference. Most of you have seen this before, but I'm sure someone will benefit from some of the aspects of the work done.

Jacks Open is a game a decided deserved a full restore. I started the restore about 3 years ago and it took me a year to restore. It used all the skills I had learn and some new techniques I pickup up along the way.

BackgroundI bought the cheap from a guy who wanted to sell the game with a Juke Box - a package deal. I had no interest in the juke box, but I wanted the pinball. So I drove over and picked it up. I set it up in my games room that night, and of course, like most EMs - It just worked.

ConditionWell - it worked ! The playfield was filthy, the cabinet was terrible - someone tried a repaint with house paint (why do people do this?), the backglass was very good, except a scratch on the outside of the glass.. What impressed me was the condition of the mechanics. The steppers, relays and score motor were "as new". The only really bad thing was that there was a coil the must of burnt the score reel at some time, as it was melted out of shape

Starting PointAfter the excitement of getting it home had settled, I had this idea to restore the game as best I could. After a couple of days, and after some thought - I took it a step further and decided it needed a repaint.. Not satisfied - I then wanted the machine to be restored "Nearly In Box" (NIB)

... So there's the challenge ...

Here's the game the day I bought it.. A bit sad looking, and it needed some attention ;

End Point

End PointSo where does the journey stop ? Fast forward 12 months...

This is the end product ;

The Journey

The JourneySince this game is finished, I'd like to post progress pictures from the first day, right up to the end result.. Kind of a journal..

First step was to remove the legs & head and have a good look around the structure of the cabinet and the paint work. Structure was ok - no repairs needed. But the paint work was CRAP.. Looked like crayons were used and a dry brush and crap paint were applied. On top of that - Some of the wood under the housepaint had reacted in some way and it looked more like bark off a tree. Nope... I'm painting this...

I used Citrus Strip from Bunnings to strip the cabinet. No fumes, no mess and it washes off in water. I used two scrapers, one wide scraper to remove the paint, and other to scrape the residue off the wide scraper. I had to do it twice in some sections as the red paint was really deep into the wood. It took 3 hours and I left the game in the sun for a few hours and waited a week before prepping it.

I tried a few different wood fillers on this cabinet, none that I was pleased with.. But I did fix most of the dints etc... Sanded with 150, 180, 320 then 600 before the first undercoat

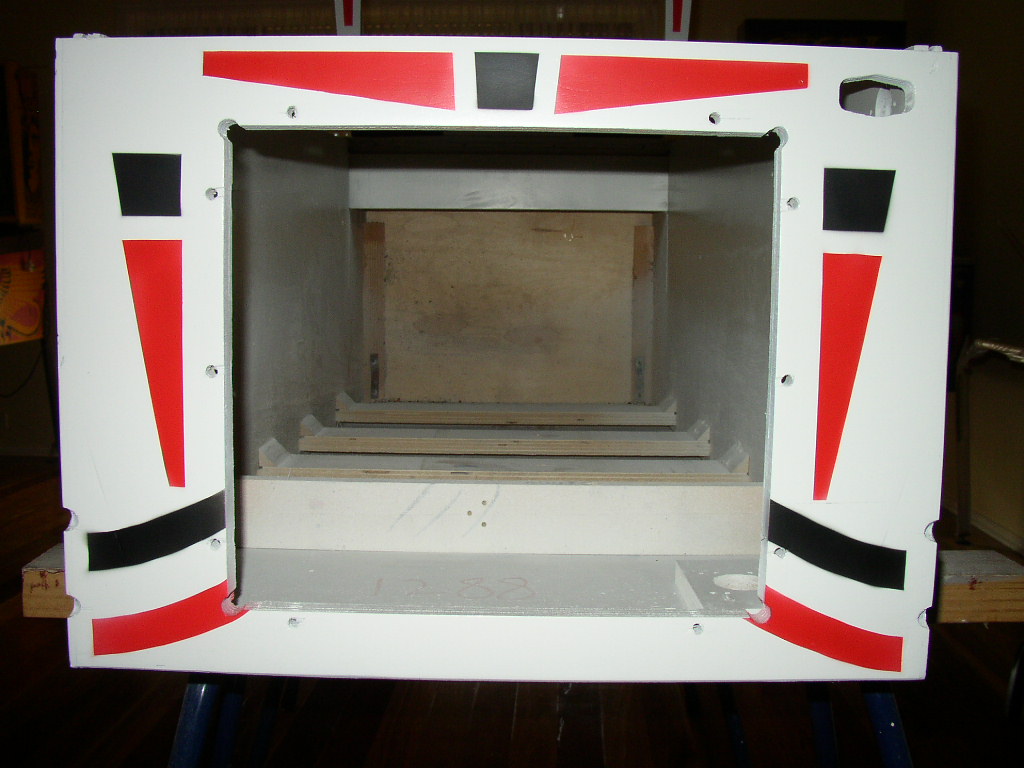

I masked off the insides of the cabinet from the undercoat.

OK - I don't recall the number of undercoats, but I think it was four. We used 600 grit wet / dry between coats, and waited about 20 minutes between coats. I used Dad's compressor and paint guns - he has been doing this for years (spray painting) - so it was easy for him - and me !

The cabinet was left out in the sun for two hours, and then placed in storage for a week...

Whilst the cabinet was getting a make over.. the playfield strip commenced. Everything was removed from topside. Boy was it dirty. First clean was with a wet rag, then nifti (sprayed on the wet rag). I spent the next 3 Days removing the ball swirl. I used ISOCOL from a chemist with 3 packets of chux magic erasers. Lots of care needs to be taken while doing this. There are sections that wore away the lacquer, and sections where the paint just lifted. Care needs top be taken here. I think to took 20 hours to get it perfect.

Before Pictures

Progress pictures - post cleanup with ISOCOL and MAGIC ERASER

While this was happening, I ordered EVERYTHING topside From Pinball Resource.

Bumper bodies, skirts, caps, flipper, posts, acorn caps, rubbers, nails, coils, rebuild kits, side rail nails, flipper buttons and housings, pincushions, legbolts... and heaps of other bits..

Sidenote - I PESTERED steve to remake the plastics set, and midway through the playfield clean, he emailed me with a release date.. So I ordered them as well !!

This is the hardest part of the resto imho. LOTS of time and patience required. Unfortunately, I don't have detailed pictures of these steps, as I just forgot. The white base color was sprayed on in one long session. I think it has 3 coats - first was thin, then two thicker. The entire cabinet was painted and left to dry in the sun, then left for 2 weeks to dry. During the two weeks, I made the stencils. Here's how I did it;

Bought a roll of tracing paper, .005 Acetate sheets, black thin permanent marker, and an exacto knife.

Prior to the resto, I traced the entire cabinet onto tracing paper and I took heaps of pictures. Initially with pencil on the tracing paper and then thin perm marker. When it was time to create the stencils, you use the tracing paper image on the bottom, and secure it to the acetate sheet on top. Trace the section that you need to be cut out of the stencil to allow the paint to pass on to the cabinet. That's a BLACK stencil for the sides of the body, head, front of the body and head. The the same for RED. So that's 12 stencils in all..Time consuming, and you need to be accurate. Then all the stencils need to be labeled and store them under a rug or the carpet so they stay flat....

The "Splatter effect"...This is easy - but you need to test on a piece of cardboard.. All Gottliebs of this era had little specs of black paint all over the cabinet - The story is that the specks detract the eye from the lack of registration of the stencils and the over spray and under spray. When researching the way the original cabinet was painted, a thin sheet of brass was held against the cab and then the color was sprayed through the brass stencil. Then the next color was sprayed. So stenciling a cabinet from the factory in the old days took minutes, not hours. But there was always overspray and underspray. The "splatter" was there to distract from these problems. So in faithfully restoring a cabinet, I wanted it as authentic and accurate as possible.

All that's needed is a toothbrush and thick black paint, although I thinned mine out and "flicked" the paint while the side I was "flicking the paint" was flat (horizontal) - that way, paint does not run. Dipping the brush into the paint than running your finger from away from you towards you along the brush "flicks" the paint randomly on the cab.. easy..

Once "splatter" is done, the RED is applied. I started on the sides. The cab must be on a flat surface with the side to be painted horizontal. The RED stencil is registered (important) on the side to be painted and then some 3M blue tape used to hold the stencil down. Mask off everything else around the stencil. Here's the secret - use large nuts, bolts, steel offcuts and anything heavy (get creative), and lay them on the stencil - this creates pressure around the edges - BUT - It keeps the end product faithful to the original, as there WILL BE overspray - because the stencil will not be completely flat..So it will look natural - not like the perfectly laser cut stencils...

Then, using a smaller volume spray gun, spray the red paint - thin coat first, then wait 5 minutes, another thin coat, than a thicker coat. All over in 10 minutes.. BEFORE the paint dries - remove the metal parts holding the stencil and carefully remove the stencil...It should come off nicely..

Repeat for all RED parts of the game...

Fast forward a week..

Repeat the process for BLACK...

Very time consuming - you need patience and a willing helper. After a week of storage..It was ready to come home. Here are the results ;

Side of the Cabinet  Front of the Cabinet

Front of the Cabinet  Front View

Front View - including the installation of polished parts

Side view

Side view with "splatter" !

Side view of the Head

Side view of the Head

Now it's just a matter of polishing and cleaning EVERY single part and installing them back on to the game...

The cleaning of the playfield took a lot of time and elbow grease. While the cabinet was drying, I started on the underside of the playfield. I replaced playfield contact switches where necessary, rebuilt the flippers using new coils, stripped and rebuilt the stepper units (bonus etc), rebuilt the bumper assemblies and tidied up any wiring.

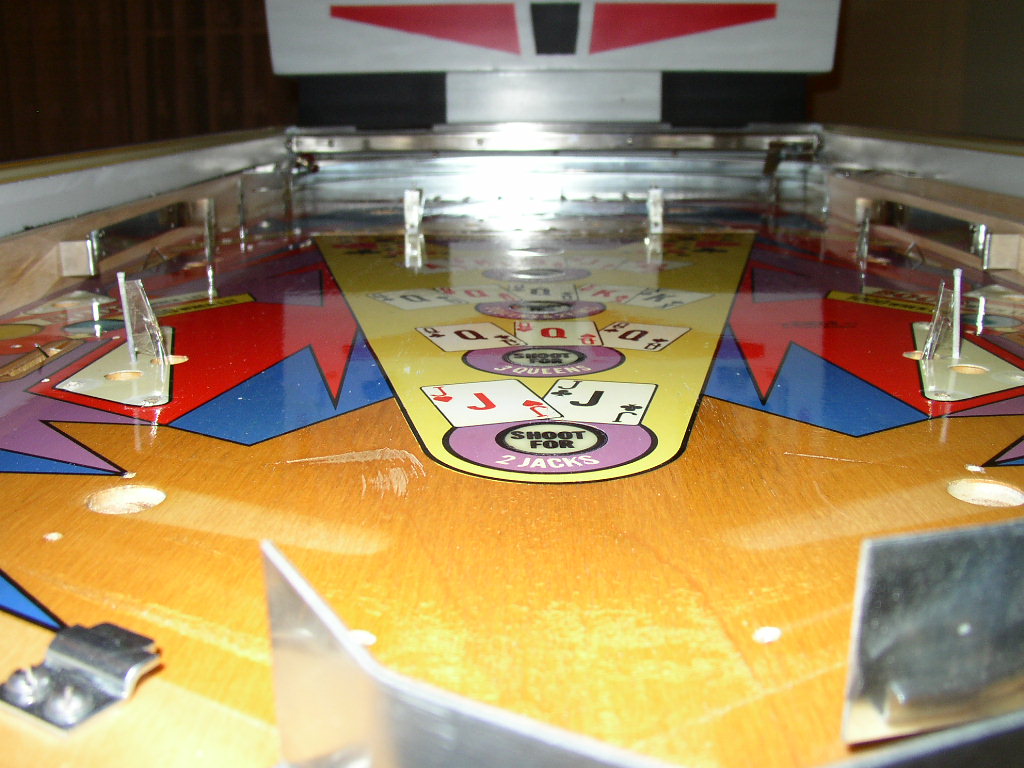

The next part was easy - installing the new playfield parts. I think just about everything is new here except the ball arch and metal guides . The wooden siderails were sanded right down.

Here's a picture inbetween waxing the playfield before intstalling the playfield parts ;

Notice the "flipper drag" - The only downside to this playfield. Not much that can be done about this without touchup and clearcoat. I never touchup or clearcoat EMs.

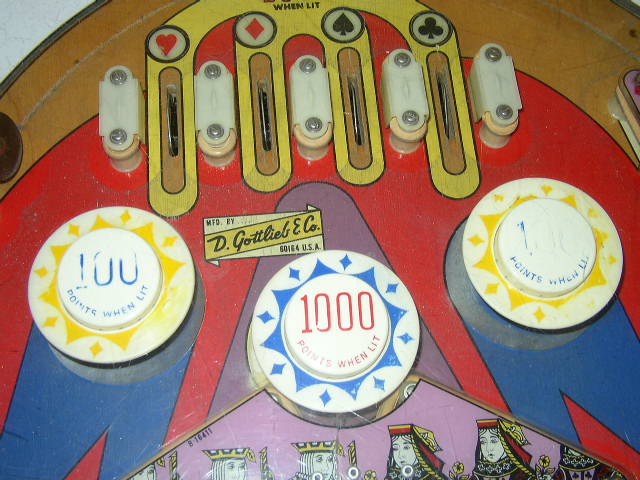

The YELLOW area under the targets is always a high traffic / wear area. After a good clean, it has come up really well. I used a sharpie to color the black circles around the inserts. This area was plagued with "ball swirl" - I'd say at least half the time was spent cleaning this area !

The Target Bank was completely rebuilt - eve to the point of polishing the mechanism. I works perfectly. Here's a progress picture of the palyfield;

You can see the lines (very thin) where the paint raised and peeled off. Especially in the LHS topmost "heart" in the yellow section. There are also other areas in this picture that have raised paint ;

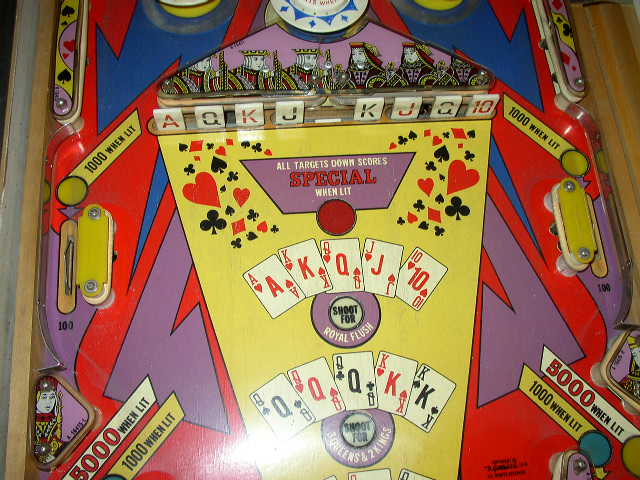

Lower Playfield and the NEW Plastics Set installed !! I BEGGED Steve from Pinball Resource to remake these plastics as the plastic above the target bank is ALWAYS broken. Cost US$76 at the time. There's some nice "shine" just below the target bank.

Here's what 4 coats of paste wax and buffing can do to a playfield. It's no clearcoat, but it is so smooth and shiney, it does give the impression that is is a clearcoat. Just hard work...

Finished Playfield - With the apron installed and instruction cards. I scanned the cards, printed them on high quality paper and then laminated them. I've cheated for this shot as the game is actually turned on - but it is a great picture to showcase the results that can be achieved with hard work and some great new parts !

End of Part 1